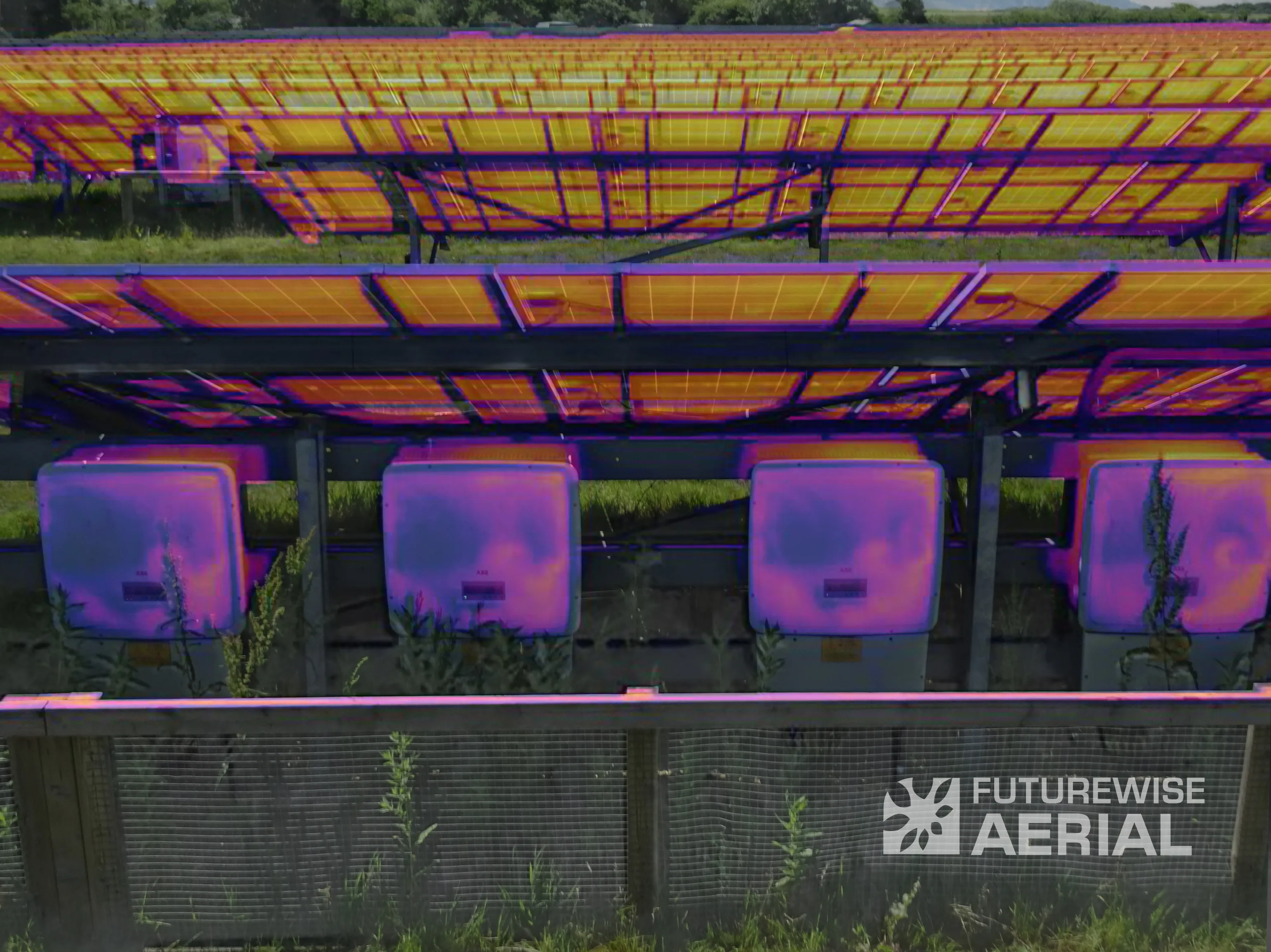

Thermal Inspection & Hotspot Detection

We offer thermal inspection as a targeted service for clients who need electrical fault detection alongside our core visual and serial number capture services. Identify hotspots, cell failures, and underperforming strings — available when you need it.

When Thermal Adds Value

Thermal inspection uses infrared cameras to detect temperature variations across your solar array. Modules with electrical faults — failed cells, poor connections, bypass diode failures — generate heat that's invisible to the eye but clearly visible in thermal imagery.

We offer thermal inspection as a targeted service for clients who need electrical fault detection alongside our core visual inspection and serial number capture services. It's particularly valuable for:

- Identifying underperforming strings and modules

- Locating electrical faults before they cause failures

- Investigating unexplained generation losses

- Comprehensive site assessments combining thermal and visual data

Faults We Identify

Hotspots

Localised areas of elevated temperature indicating cell damage, shading issues, or connection problems. Hotspots reduce output and can lead to module failure if left unaddressed.

Cell Failures

Individual cells that have failed or are underperforming, visible as temperature anomalies within the module. Failed cells reduce module output and can trigger bypass diode activation.

String Outages

Complete or partial string failures that significantly impact array output. Thermal imaging quickly identifies which strings are offline or underperforming.

Bypass Diode Activation

When bypass diodes activate to protect damaged cells, they create characteristic thermal patterns. Persistent activation indicates underlying cell problems.

Connection Issues

Poor connections at junction boxes, connectors, or cabling create resistance and heat. Thermal inspection locates these issues before they cause failures.

PID (Potential Induced Degradation)

Some forms of PID create thermal signatures that indicate affected modules, helping identify degradation patterns across your array.

Targeted Thermal Analysis

Unlike providers who offer only thermal inspection, we position thermal as part of a comprehensive inspection approach. Thermal imaging tells you something is wrong — but you still need visual inspection to see the physical defect, and serial number capture to identify exactly which module it is.

Our thermal inspection includes:

- Radiometric thermal imaging capturing precise temperature data

- Systematic coverage of your entire array

- Analysis against IEC standards for thermal anomaly classification

- Integration with visual inspection and serial number data

- Clear reporting with anomaly locations and severity ratings

When to Add Thermal Inspection

Investigating Performance Losses

If your site is underperforming against expectations, thermal inspection can quickly identify which modules or strings are responsible.

Comprehensive Site Assessment

For a complete picture of site condition, combining thermal with visual inspection covers both electrical faults and physical defects.

Commissioning Verification

New installations benefit from thermal inspection to catch installation defects, connection issues, and faulty modules before warranties begin.

Insurance and Due Diligence

Some insurance policies and acquisition processes require thermal inspection as part of site assessment.

Maximum Value: The Complete Inspection

Thermal inspection is most effective when combined with our visual inspection and serial number capture services. One site visit, one data capture, comprehensive results:

| Service | What It Finds | What It's For |

|---|---|---|

| Serial Number Capture | Module identification | Warranty claims, asset registry |

| Visual Inspection | Physical defects | Warranty evidence, condition assessment |

| Thermal Inspection | Electrical faults | Performance issues, fault location |

Most clients who need thermal also need the visual and serial data to action what they find. We recommend discussing your specific requirements so we can scope the right combination for your needs.

Standards Compliance

Our thermal inspection follows established industry standards for solar PV thermography:

- IEC 62446-3 — Requirements for photovoltaic system testing and documentation, including thermographic inspection

- Anomaly classification using industry-standard temperature delta thresholds

- Radiometric data capture for accurate temperature measurement

- Appropriate environmental conditions for reliable results

We'll advise if conditions aren't suitable for thermal inspection and reschedule if necessary to ensure data quality.

See Our Services in Action

Man vs Drone: The Statistics

How drone-based inspection outperformed manual methods across 7 UK sites.

View Case Study →Busbar Corrosion & Delamination

Comprehensive inspection combining visual and thermal data at scale.

View Case Study →Serial Number Capture Results

500,000+ serial numbers mapped with 99%+ verification accuracy.

View Case Study →Frequently Asked Questions

What does drone thermal inspection detect?

Thermal inspection uses infrared cameras to detect temperature variations across your solar array. It identifies hotspots, cell failures, string outages, bypass diode activation, connection issues, and some forms of Potential Induced Degradation (PID).

When should I add thermal inspection to my site assessment?

Thermal inspection is most valuable when investigating unexplained performance losses, conducting commissioning verification of new installations, performing comprehensive site assessments, or meeting insurance and due diligence requirements.

What standards does your thermal inspection follow?

We follow IEC 62446-3 requirements for photovoltaic system thermographic inspection, including radiometric data capture for accurate temperature measurement and anomaly classification using industry-standard temperature delta thresholds.

Why combine thermal with visual inspection?

Thermal imaging tells you something is wrong electrically, but visual inspection reveals the physical defect causing the issue. Combined with serial number capture, you get a complete picture: what's wrong, what it looks like, and exactly which module is affected — all from one site visit.

Does weather affect thermal inspection results?

Yes. Thermal inspection requires appropriate environmental conditions — sufficient irradiance, low wind, and stable cloud conditions — for reliable results. We'll advise if conditions aren't suitable and reschedule if necessary to ensure data quality.

Discuss Your Inspection Requirements

Whether you need standalone thermal inspection or want to combine it with our visual and serial number services, we can help scope the right approach for your site.