High

Definition Visual

Inspection

High Definition Visual Inspection – For the complete picture of your asset health.

High Definition Visual Inspection (HDVI) is a vital part of Solar PV maintenance, to detect developing serious issues in the early stages.

Armed with a detailed report of how many anomalies are present, asset owners can make informed decisions about their next course of action, whether that is module testing and electroluminescence, or direct to the manufacturer for a warranty claim.

Other uses include benchmarking for newly built sites, and serial number detection.

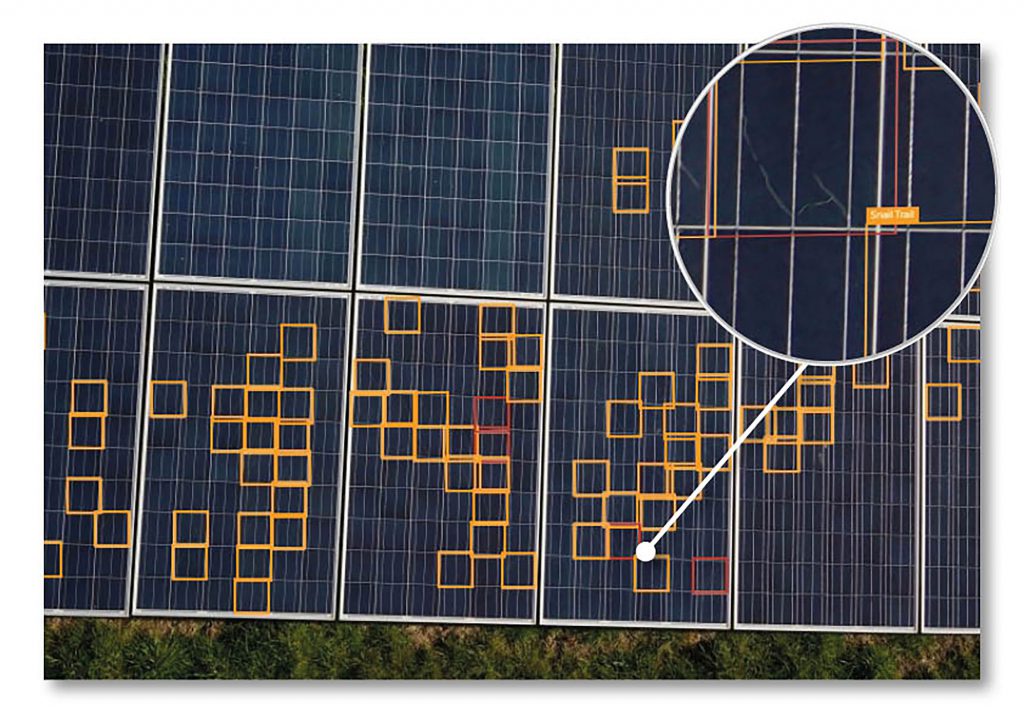

Example cell-level defects that can be detected are:

Snail Trails

Discolouration

Delamination

Busbar faults

Traditionally solar plants have been inspected manually, but this presents many challenges such as:

Very labour intensive

Results are of mixed quality

Increased risk to workforce

Vast amounts of data management and reporting

Large arrays may require access equipment

Watch how using our service can reduce labour costs by 5000%

https://youtu.be/-Ew3b0zyxOAWhy Conventional Drone Inspections Will Not Reveal All Your IssueS

Using traditional drones to scan an asset, using thermal cameras, is useful for detecting issues that are already developed but is very unlikely to reveal any indication of the types of anomalies which are visible using HDVI.

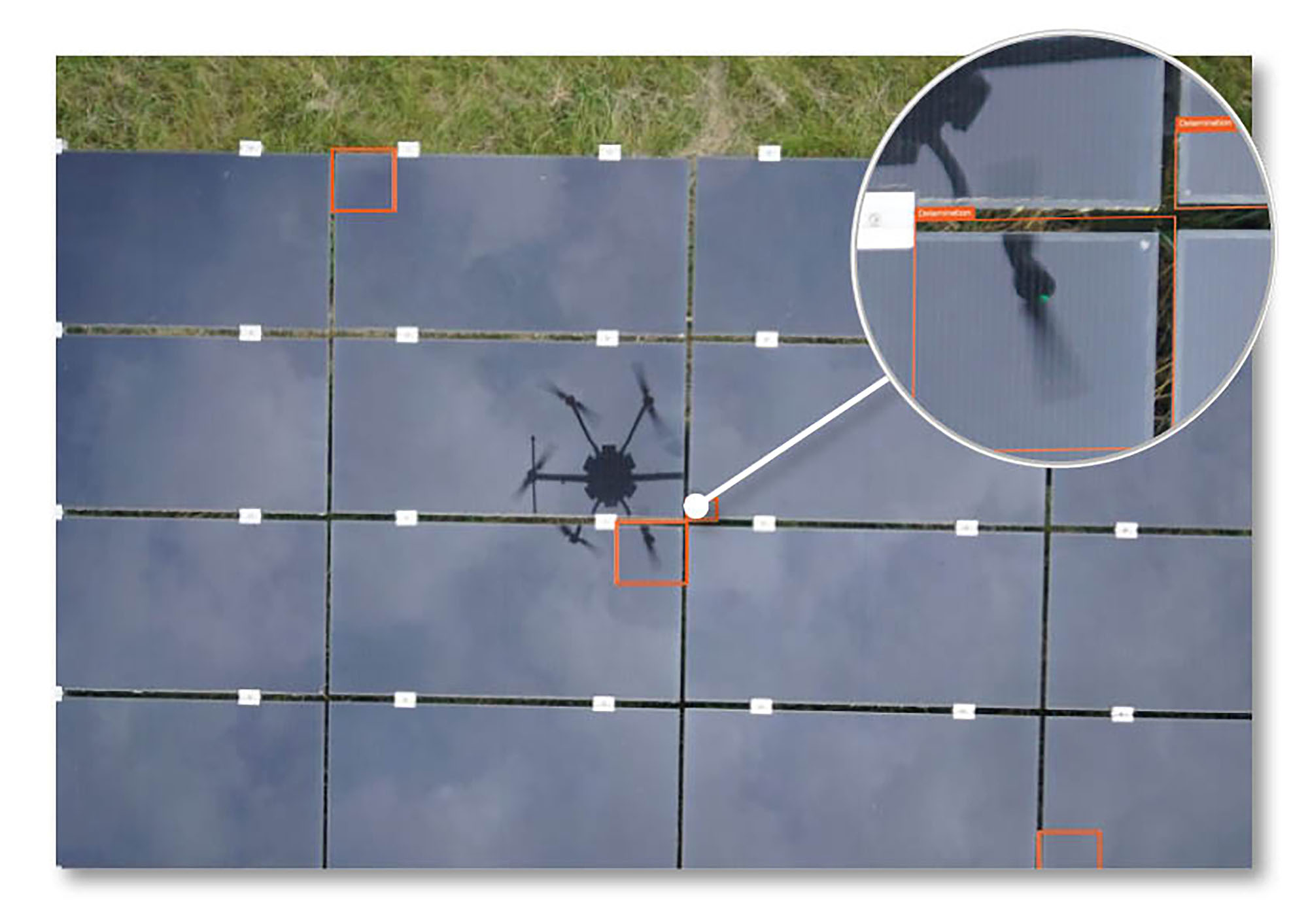

Off-the-shelf drones have RGB cameras, but they are not entirely suitable for HDVI as they are of low picture quality in comparison. With conventional drone inspections, the drone is predominantly at a higher altitude above the PV modules and cannot capture high resolution images.

Additionally, standard equipment is not able to overcome the extra challenges that HDVI presents in the form of spatial awareness, collision avoidance and positioning accuracy.

Our bespoke aircraft and sensor clearly captures an instance of delamination.

High definition visual inspection by drone requires extremely powerful cameras to be flown with centimetre precision in the correct environment. We have developed bespoke aircraft and workflow process, to capture the highest resolution images possible in the most cost-efficient manner, capturing up to 750 modules per minute.

Machine learning algorithms are deployed to analyse every image in minute detail. Affected modules are then classified and reported in variety of formats reporting the module locations, the number of modules and number of cells affected.

CONTACT US NOW on email [email protected] or call 0333 990 9847

CLICK HERE to book your free online consultation and demonstration during which we will explain in detail how a high definition visual inspection (including a professional, detailed, and thorough report) will provide you with the complete picture of your asset health.

SERVICES WE OFFERWIND TURBINE INSPECTIONS

SOLAR SERVICES

CLOSE INSPECTION & SURVEY

MAPPING AND GIS

INSPECTION PORTAL

3D MODELLING

GROUND CONTROL SOFTWARE

CONSULTANCY AND TRAINING

DETAILED THERMAL INSPECTION

“The service and data delivered to us by Futurewise Aerial was top class. The findings saved us loads of time and lost efficiency, thanks.”

Ryan McShea – Empower Energy Ltd