Water Ingress & Serial Number Capture for Warranty Claims

How drone-based serial number capture turned a complex warranty challenge into a multi-million-pound claim — 99.8% accurate, 8x faster, with zero downtime.

Client Challenge

Widespread module failure due to water ingress required a solar panel serial number capture to verify a multi-million-pound warranty claim.

Our Approach

Ultra high-resolution drone imaging and our proprietary processing scripts to capture and verify every serial number on site.

Results

99.8% accuracy | 8x faster than manual methods | Multi-million-pound warranty claim enabled.

Turning a Warranty Challenge into Actionable Results

A UK solar farm experiencing widespread water ingress needed fast, accurate proof to activate a multi-million-pound warranty claim. Manual serial number collection would have taken weeks and halted production. Futurewise Aerial delivered a verified dataset in days — 99.8% accurate, 8x faster than manual methods, with zero downtime.

Widespread Module Failure Requiring Verified Proof

A large-scale solar farm was experiencing a high rate of module failure, suspected to be caused by water ingress in a specific batch of panels. The asset owner needed to activate a multi-million-pound warranty claim, but this required an accurate, verifiable list of all affected panel serial numbers to prove they were part of the faulty batch.

A manual inspection was quoted as taking several weeks and would require shutting down sections of the farm, leading to unacceptable production losses.

What Were We Looking For?

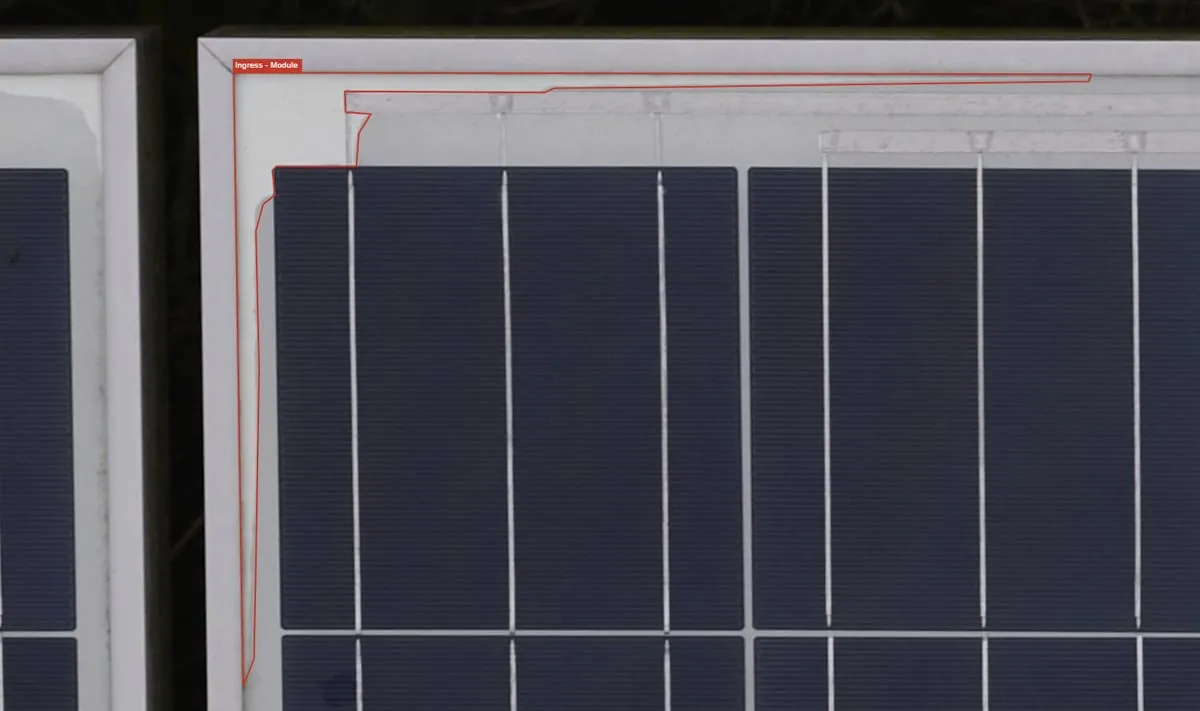

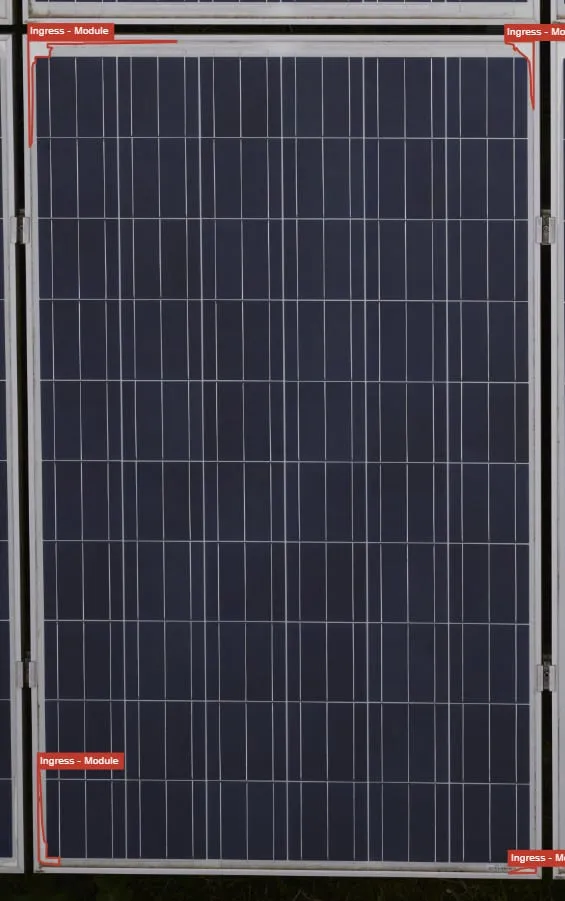

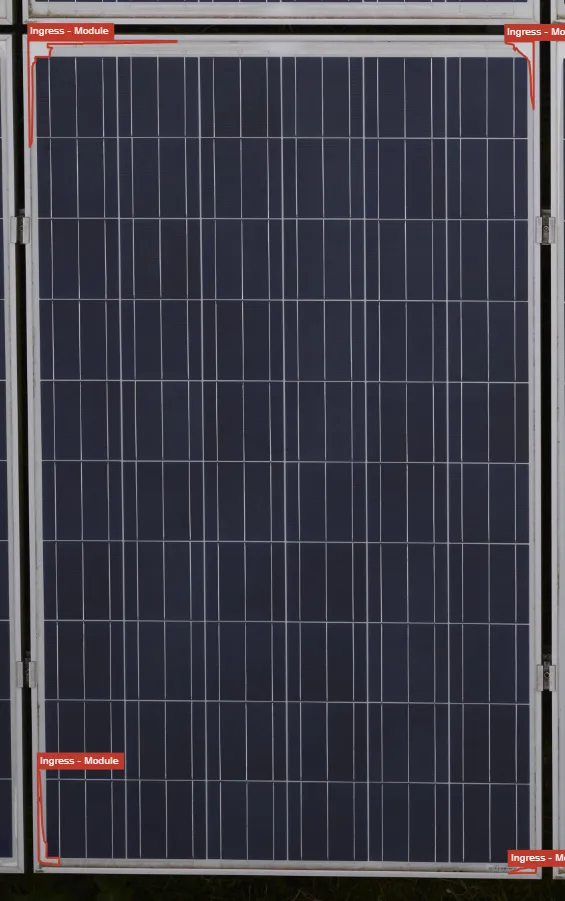

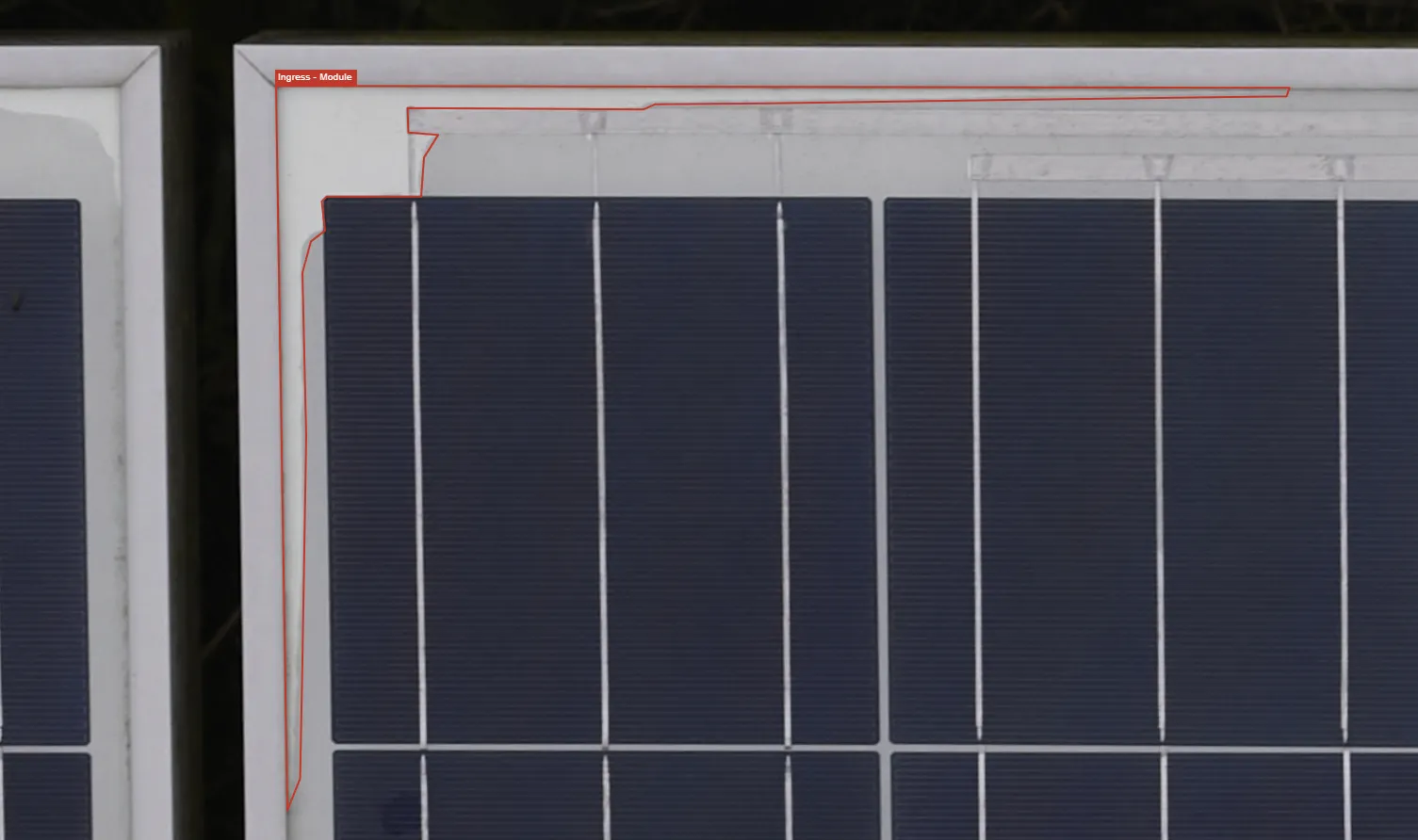

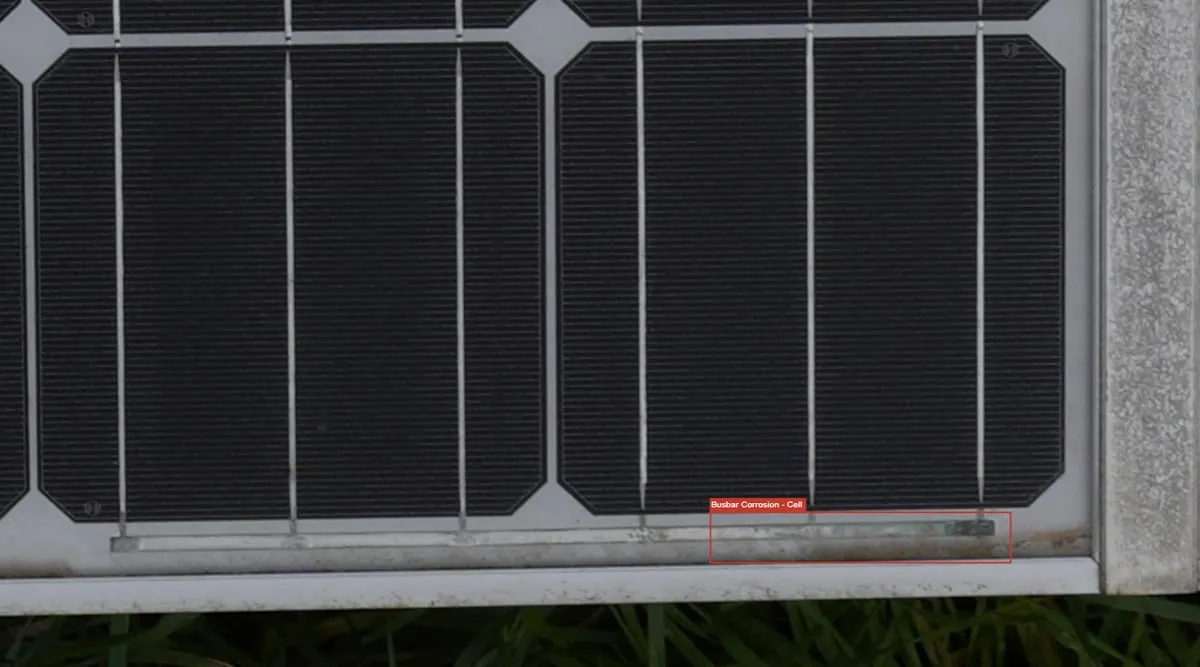

Delamination occurs when water penetrates the panel, causing internal layers to separate. Visible as white patches or clouding, this defect progressively degrades performance and necessitates replacement under warranty.

High-Definition Fault Images & Serial Number Capture

Futurewise Aerial was deployed to conduct a full, high-resolution aerial survey. Using our specialist, state-of-the-art cameras, we captured panel-level imagery across the entire site. This data was then processed by our proprietary in-house scripts, which automatically located, read, and extracted the serial number from each individual module.

The data was compiled into a single, verified database for the client — ready for immediate use in their warranty claim submission.

Inspection Findings

The inspection uncovered widespread degradation concentrated in key areas of the farm. White patches and clouding revealed where water had penetrated the panel layers, causing progressive delamination and performance loss.

These findings confirmed the non-random distribution of faults — a telltale sign of manufacturing issues requiring immediate warranty action.

What the Client Received

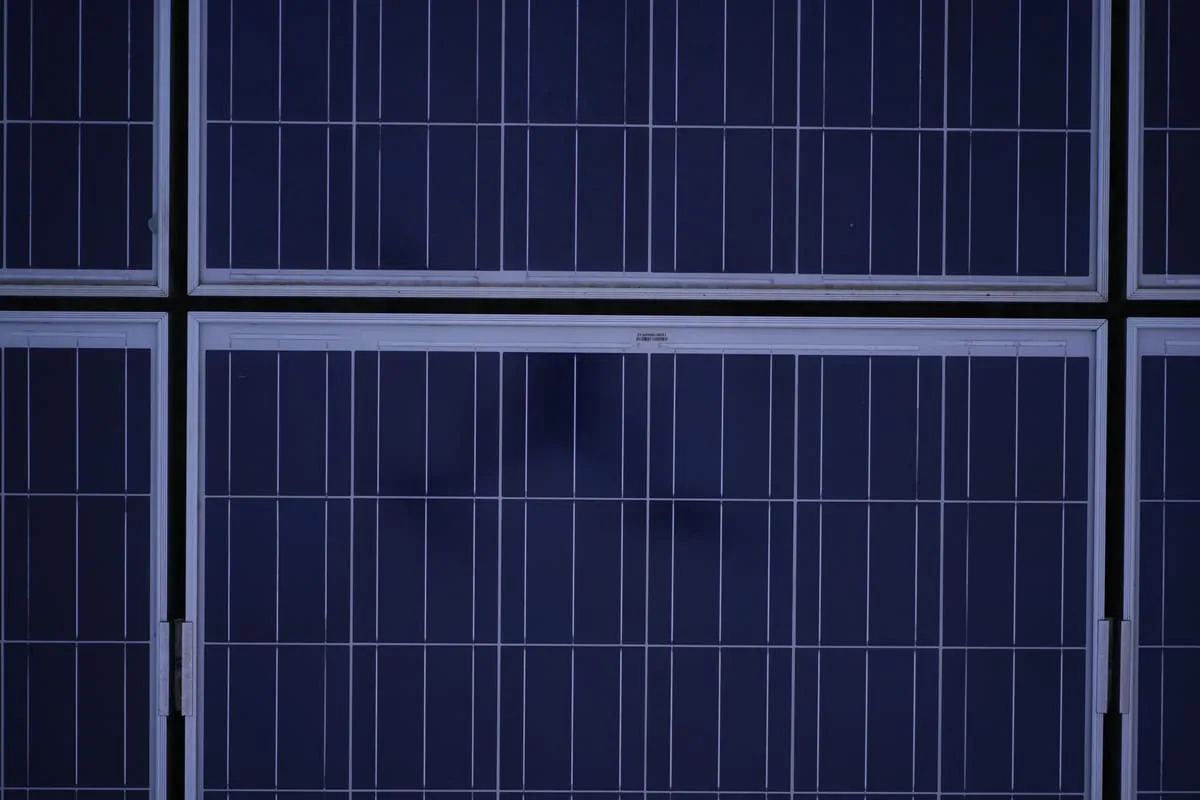

Digital Twin

A digital map of every module on site, geolocated and indexed for easy reference.

Full Module Table

Complete dataset of serial numbers, module IDs, and flagged anomalies.

High-Resolution Images

Detailed imagery for each module, providing visual evidence of condition.

Defect Register

Comprehensive log of all identified defects with supporting evidence.

Explore Our Work

Detecting Busbar Corrosion & Delamination

Ultra high-resolution drone inspection uncovering widespread busbar corrosion and mapping serial numbers.

View Case Study →

Market-Leading Serial Number Capture

Fast, precise, and verifiable panel-level data for asset managers, owners, and operators.

View Case Study →

Man vs Drone: The Statistics

Side-by-side comparison demonstrating drone inspection's 5x faster completion and zero safety incidents.

View Case Study →Facing a Similar Challenge?

Get in touch with our team for a no-obligation consultation to see how we can help you.