Man vs Drone: Serial Number Collection Compared

Data from 7 UK solar farms proves why leading asset managers are switching to aerial methods for serial number capture.

The Challenge

Manual serial number collection required 120km+ of walking across 7 UK sites, with weeks of work and significant safety risks from working under modules.

Our Approach

Drone-based capture using ultra high-resolution cameras and proprietary processing scripts across all 7 sites.

Results

5x faster completion | 98.5% capture rate | Zero safety incidents across all sites.

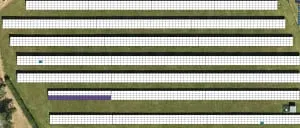

Serial Number Capture at Scale Across 7 Sites

When a portfolio of solar farms needed serial numbers collected to support ongoing warranty claims, the scale of the challenge became clear. Across 7 sites in the UK, modules with short circuit diodes had been identified through thermal inspection. Now, each affected panel's serial number needed capturing to submit the warranty claim.

The modules were randomly scattered throughout each site, and the asset manager faced a choice: deploy manual teams to walk the rows and scan each panel, or commission Futurewise Aerial's drone-based capture service. The data from this project demonstrates exactly why leading asset managers are switching to aerial methods.

Why Manual Inspection Falls Short

Traditional manual inspection of solar farms requires teams of technicians to physically access each panel, often involving scaffolding, cherry pickers, or working at height across vast sites. This approach is not only time-consuming and expensive, but creates significant health and safety risks.

For asset managers, the costs extend beyond labour — production shutdowns, insurance premiums, and weeks of planning all add to the burden. The industry needed concrete evidence comparing manual methods against modern drone technology to make informed decisions about their inspection strategies.

What Were We Measuring?

We measured drone-based serial number capture against manual methods across five critical metrics to provide a data-driven comparison.

Drone-Based Serial Number Capture at Scale

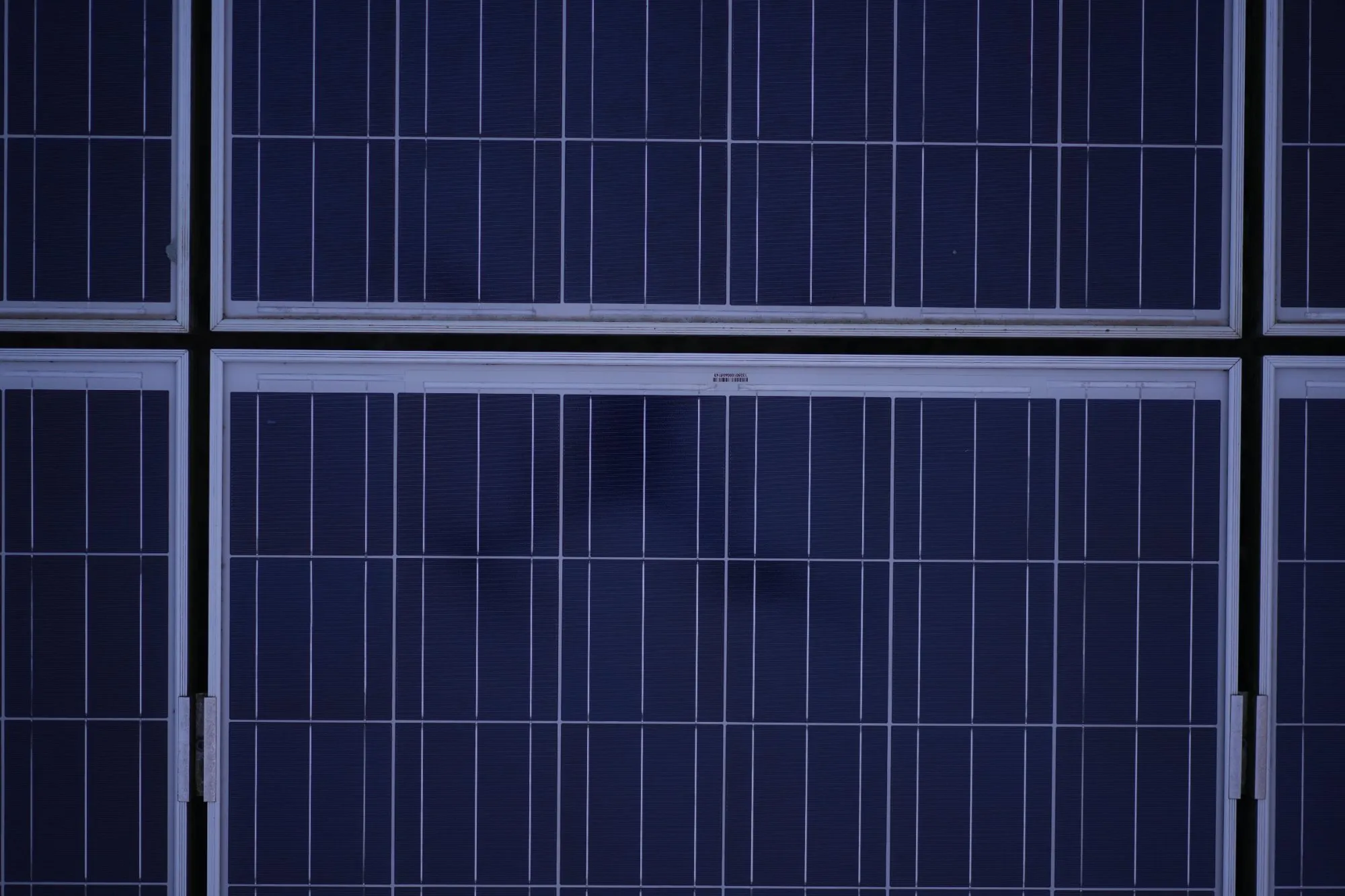

Futurewise Aerial was commissioned to capture serial numbers across all 7 sites. Using our state-of-the-art aerial cameras, we flew over the modules quickly and safely, capturing imagery detailed enough to read each panel's serial number from the air.

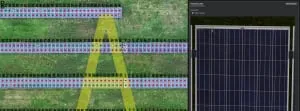

Our proprietary data processing scripts then extracted and verified each serial number, cross-referencing with panel locations to create a complete, warranty-ready dataset.

Manual Method: Teams of operatives walking 120km+ over several weeks, working under modules with trip, bump and shock hazards.

Drone Method: Autonomous flights capturing panel-level imagery, processed through proprietary scripts to deliver verified serial numbers with full geolocation data.

The result? Data collected in just 20% of the usual time — effortlessly and quickly flying over the modules without injury risk.

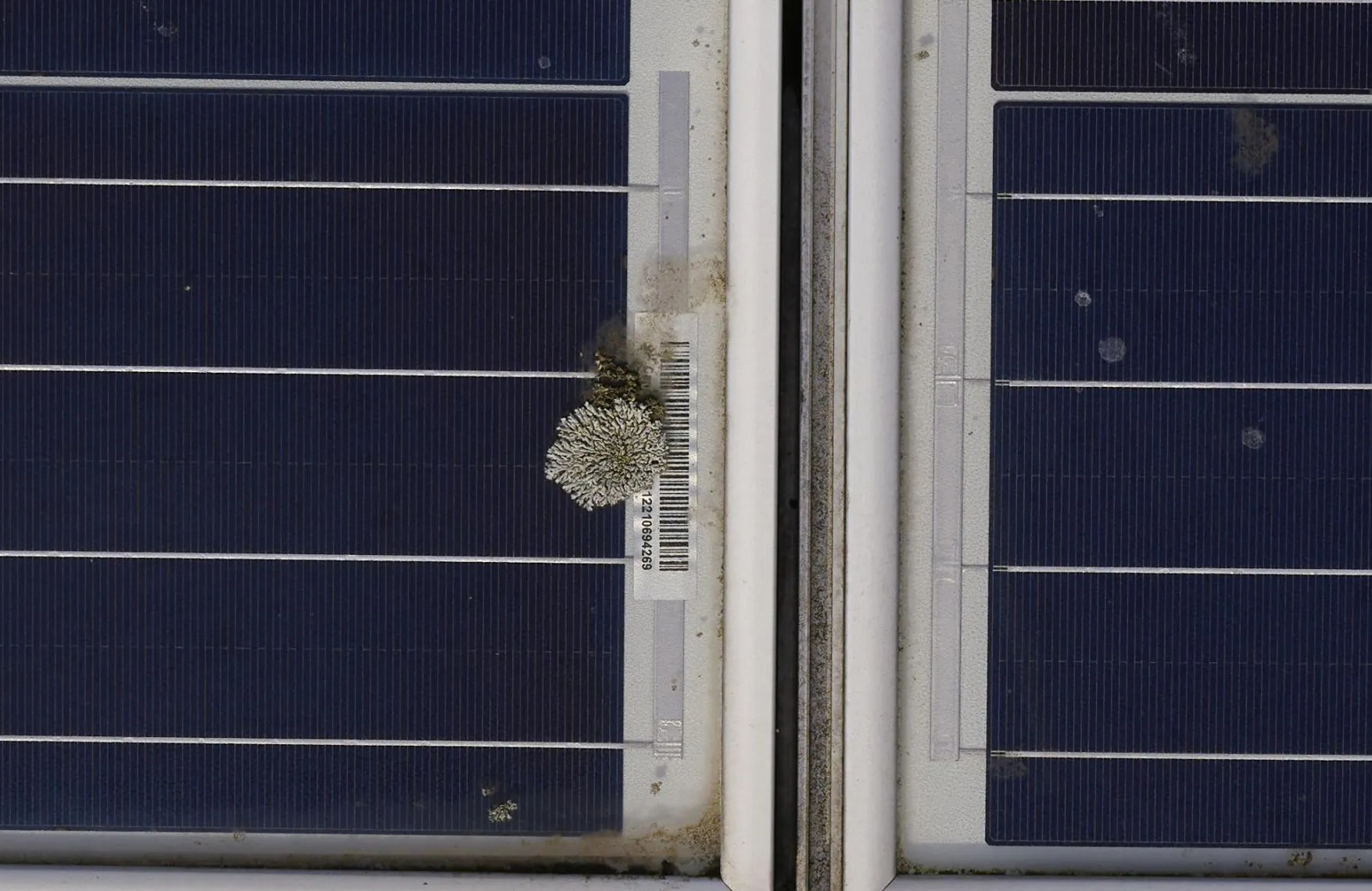

Serial capture in challenging conditions

What the Client Received

Digital Twin

A digital map of every module with precise geolocation across all 7 sites.

Full Module Table

Serial numbers, location IDs, coordinates, and component IDs for each panel.

High-Resolution Images

Detailed imagery for each module captured during the aerial survey.

Defect Register

Flagged panels with supporting evidence for unreadable or damaged serial numbers.

Explore Our Work

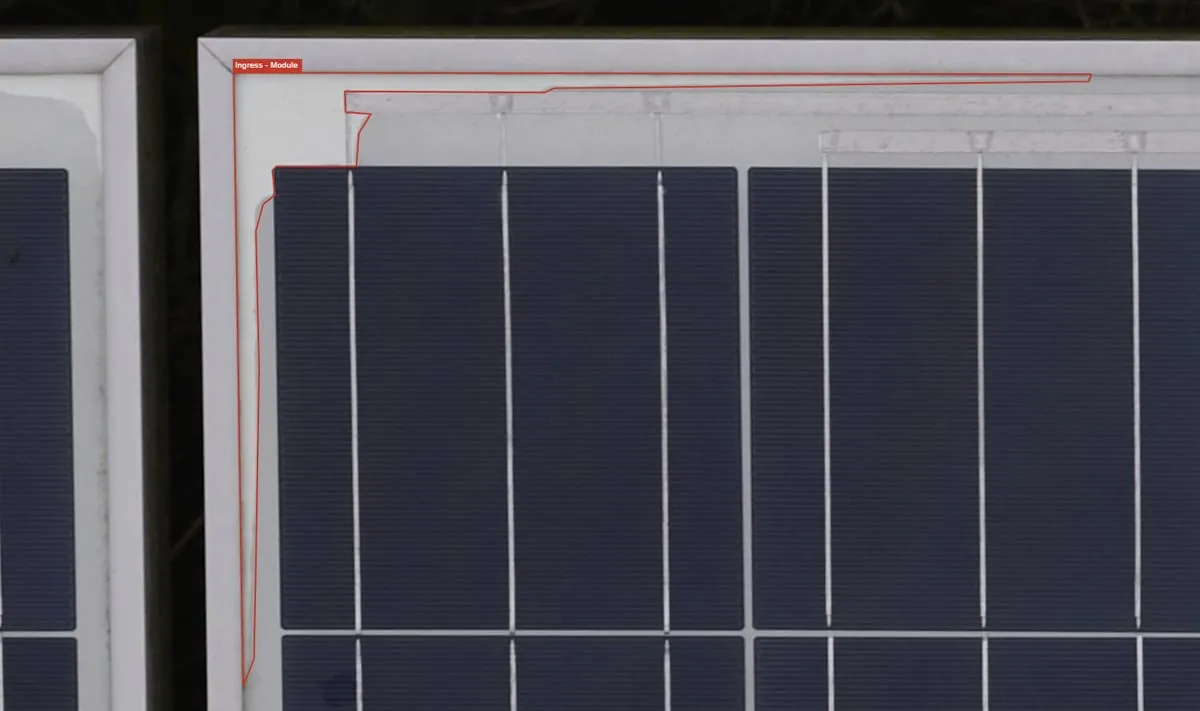

Water Ingress & Serial Number Capture

A UK solar farm needing fast, accurate proof to activate a multi-million-pound warranty claim.

View Case Study →

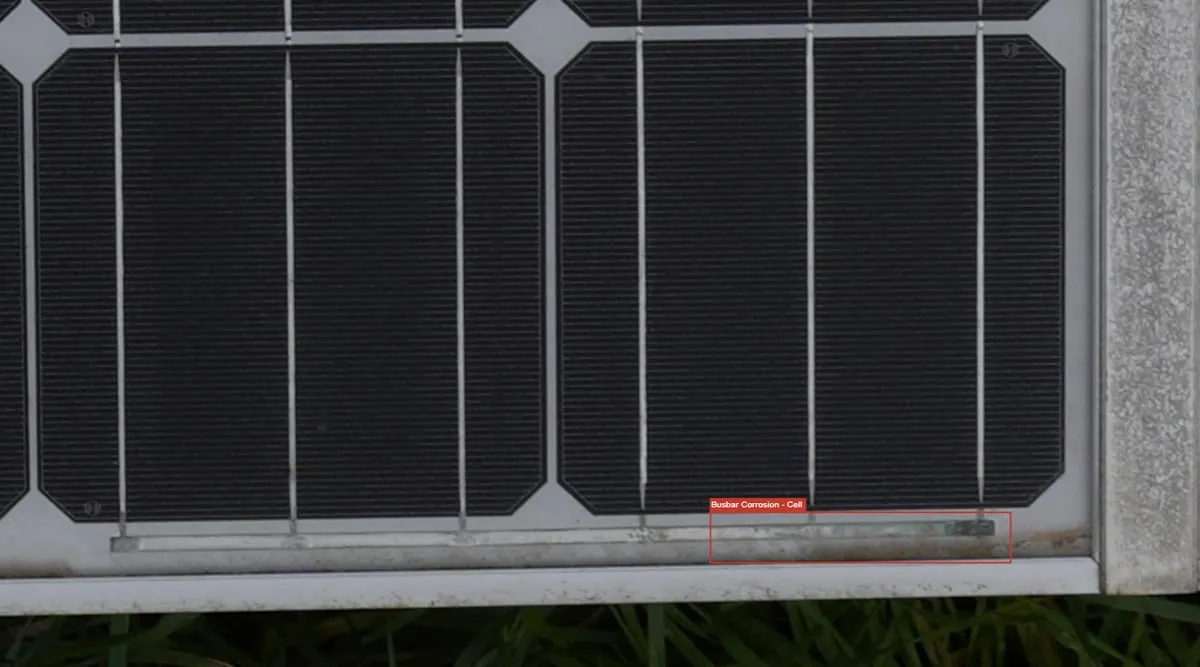

Detecting Busbar Corrosion & Delamination

Ultra high-resolution drone inspection uncovering widespread busbar corrosion and mapping serial numbers for warranty claims.

View Case Study →

Market-Leading Serial Number Capture

Fast, precise, and verifiable panel-level data for asset managers, owners, and operators.

View Case Study →Ready to Switch to Aerial Methods?

Get in touch with our team for a no-obligation consultation to see how we can help you.