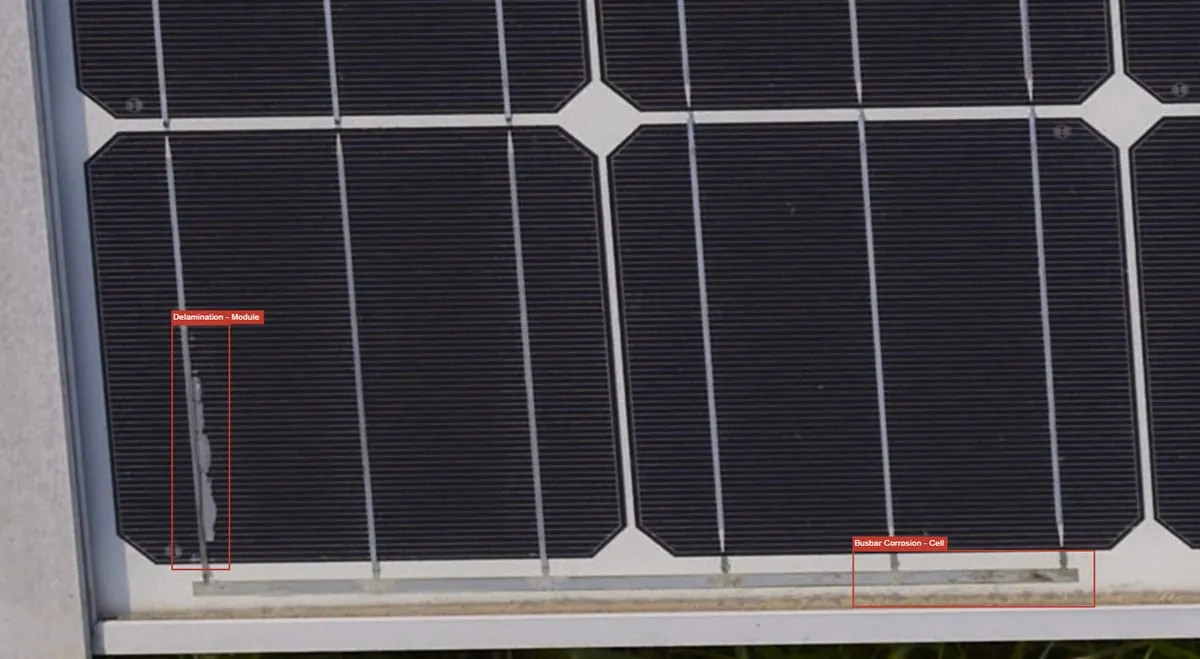

Detecting Busbar Corrosion & Delamination

How ultra high-resolution aerial inspection revealed clustered fault patterns, verified serial numbers, and enabled swift warranty action on a UK solar farm.

Client Challenge

Suspected widespread module degradation and corrosion with a random distribution pattern. Second row of modules hard to reach and inspect manually.

Our Approach

Drone inspection to capture near 'naked-eye' resolution images of every module, with automated fault diagnosis and serial number collection.

Results

3,200+ critical defects identified | Targeted replacement enabled | All mapped to digital twin for full traceability.

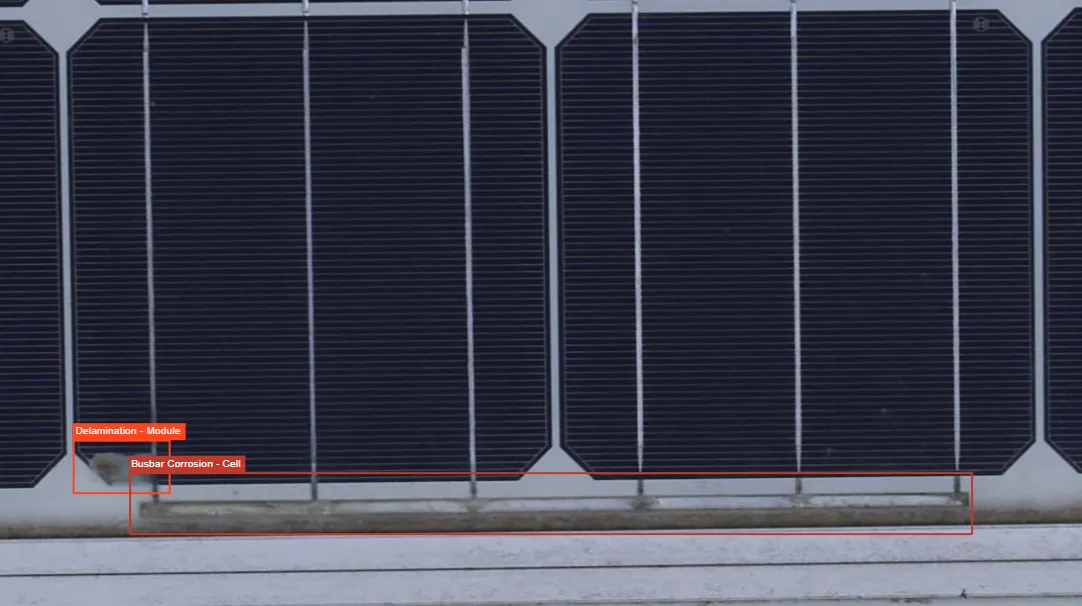

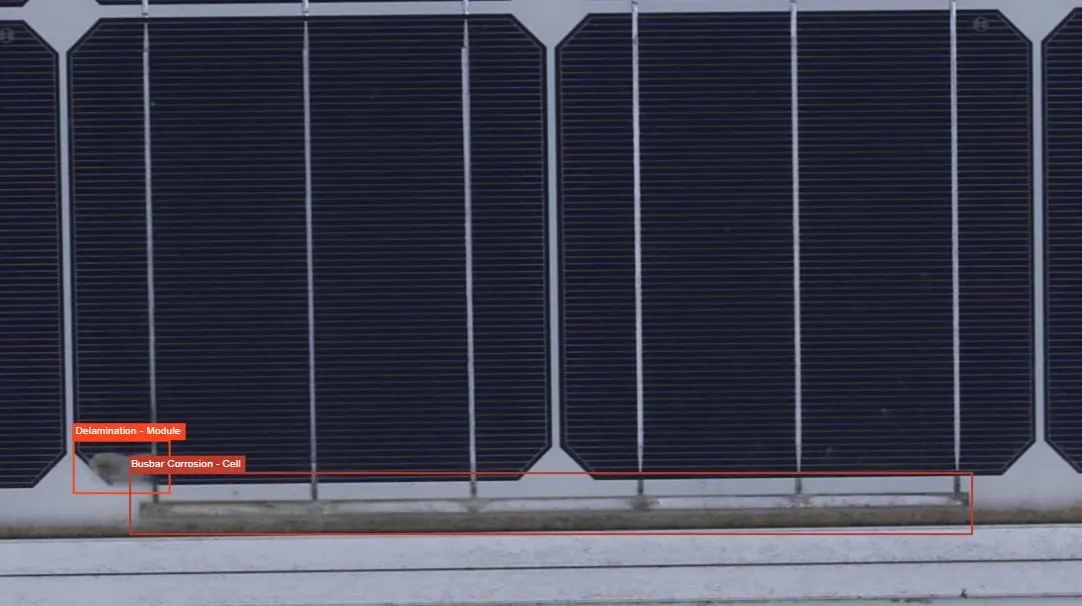

Uncovering the Full Scope of Busbar Corrosion

When a UK solar farm needed to understand the scope of busbar corrosion affecting their asset, Futurewise Aerial delivered comprehensive aerial inspection revealing clustered fault patterns across key strings. The non-random distribution pointed to manufacturing or handling issues, while our verified serial numbers and precise fault mapping enabled swift warranty action and prevented further escalation of failures.

Hidden Degradation Across a Large-Scale Solar Farm

An asset manager for a large-scale, ground-mounted solar farm in the UK suspected widespread module degradation across their portfolio. They were particularly concerned about difficult-to-detect issues like busbar corrosion and delamination, which are missed by standard aerial surveys.

The client required highly detailed, panel-level data to accurately assess the condition of their assets and make informed decisions about future maintenance and replacements. The second row of modules was especially hard to reach and inspect manually, making traditional assessment methods impractical.

What Were We Looking For?

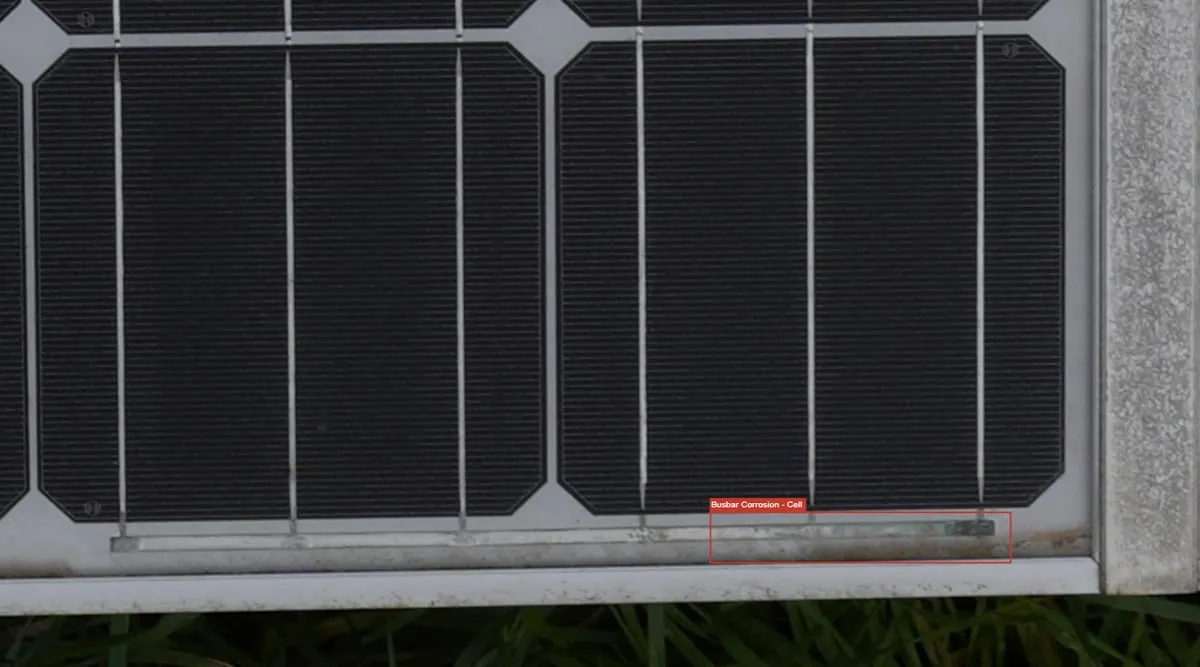

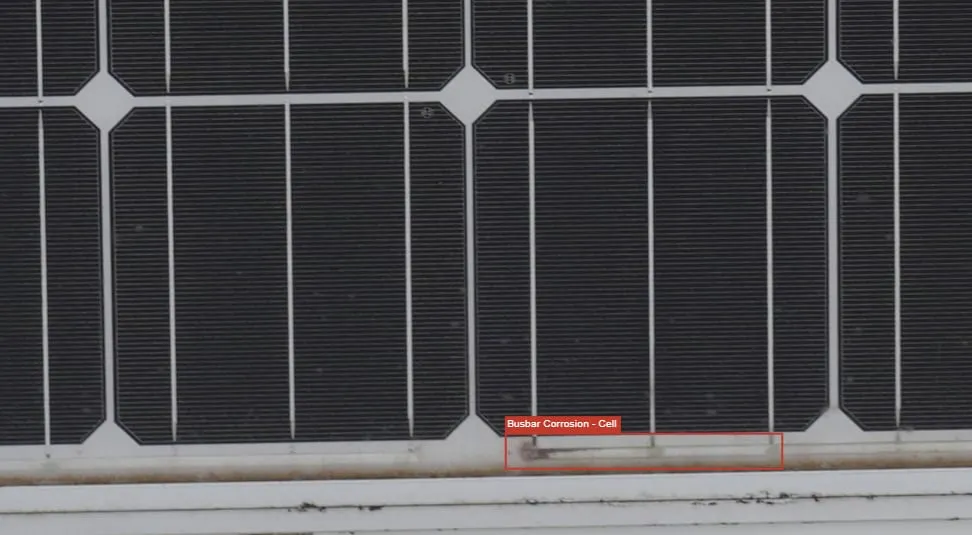

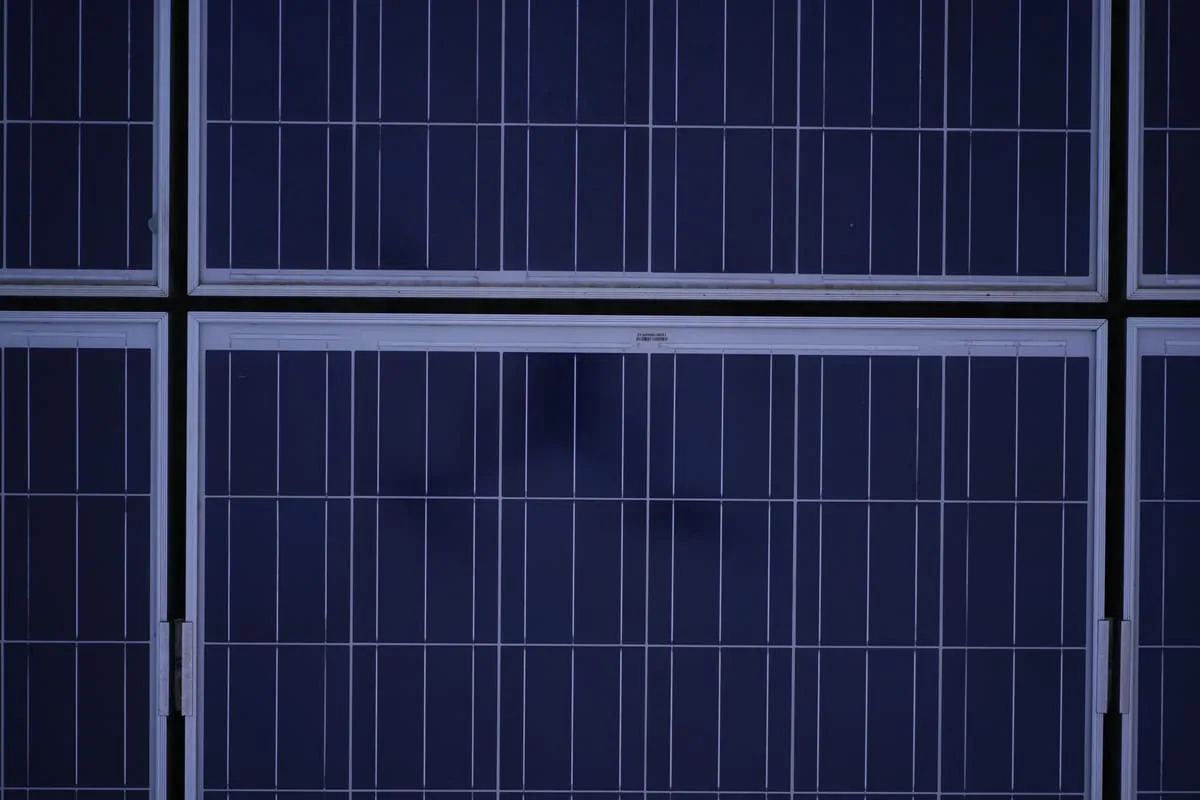

Busbar corrosion appears as dark degradation along the panel's internal metal strips, typically accompanied by delamination — white patches or bubbling where protective layers separate from the cells. These defects compromise electrical performance and indicate batch or moisture-related failures that may affect large numbers of panels across a site.

Specialist High-Definition Busbar Corrosion Inspection

Futurewise Aerial was commissioned to perform an ultra high-resolution visual inspection of the entire solar farm. Using our state-of-the-art aerial cameras, we captured imagery detailed enough to identify subtle, panel-level anomalies from the air. Our proprietary data processing scripts then analysed this imagery, efficiently flagging defects like corrosion, delamination, and discolouration that are invisible to the naked eye from the ground.

In addition to identifying the visual anomalies, our ultra high-resolution cameras allowed us to perform a second critical function on the same flight. We integrated our market-leading Solar Panel Serial Number Capture service to create a complete, verifiable asset registry.

This powerful combination cross-referenced the visual damage with the exact panel serial number, providing the client with indisputable data for their warranty claims.

Inspection Findings

The inspection uncovered widespread degradation concentrated in key areas of the farm. Dark discolouration along busbars indicated progressive corrosion, while white patches revealed where protective layers had separated from the cells.

These images captured the non-random distribution of faults — a telltale sign of manufacturing issues requiring immediate warranty action.

What the Client Received

Digital Twin

A digital map of every module on site, geolocated and indexed for easy reference.

Full Module Table

Complete dataset of serial numbers, module IDs, and flagged anomalies.

High-Resolution Images

Detailed imagery for each module, providing visual evidence of condition.

Defect Register

Comprehensive log of all identified defects with supporting evidence.

Explore Our Work

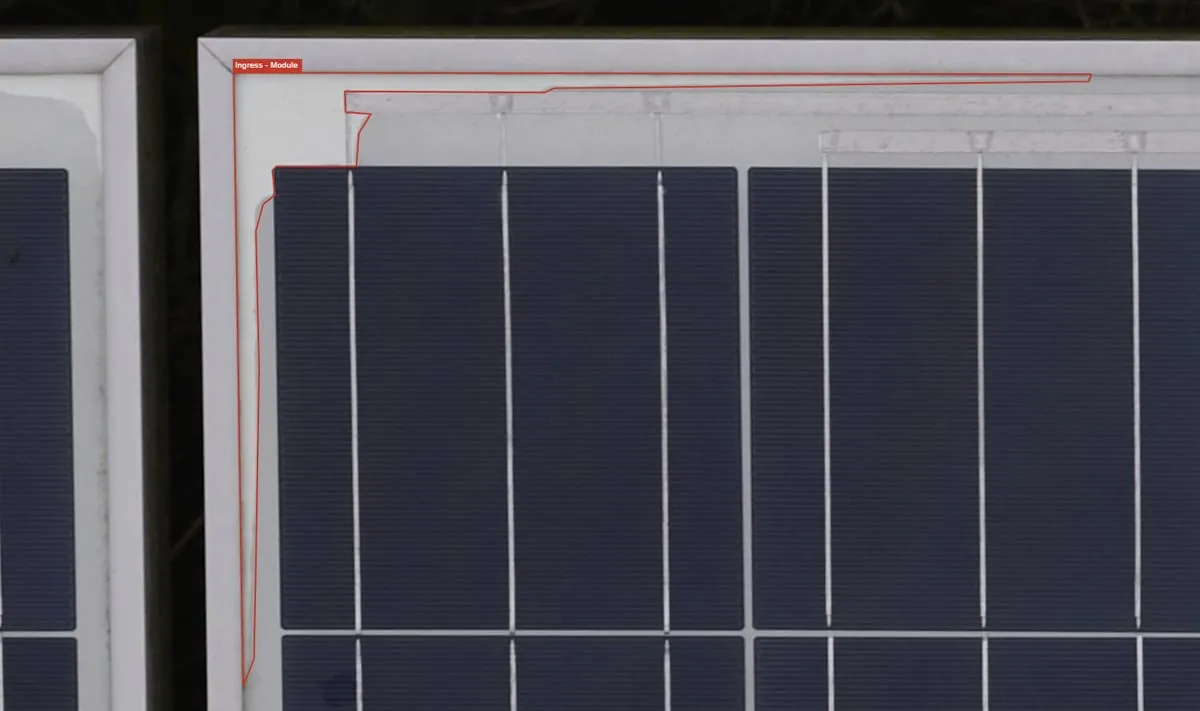

Water Ingress & Serial Number Capture

A UK solar farm needing fast, accurate proof to activate a multi-million-pound warranty claim.

View Case Study →

Market-Leading Serial Number Capture

Fast, precise, and verifiable panel-level data for asset managers, owners, and operators.

View Case Study →

Man vs Drone: The Statistics

Side-by-side comparison demonstrating drone inspection's 5x faster completion and zero safety incidents.

View Case Study →Facing a Similar Challenge?

Get in touch with our team for a no-obligation consultation to see how we can help you.