AI-Powered Detection of Mismatched Solar Modules

How drone imagery and AI defect detection identified mismatched PV modules at a Welsh solar farm — replacing days of manual inspection with fast, objective, engineer-ready results.

Client Challenge

A solar farm required identification of mismatched PV modules — panels differing from neighbours, indicating incorrect replacements or mixed batches.

Our Approach

High-resolution drone imagery processed through AI-powered defect detection to automatically flag mismatched modules across the array.

Results

4 mismatched modules identified | GPS-located | Audit-ready PDF reports with severity classification.

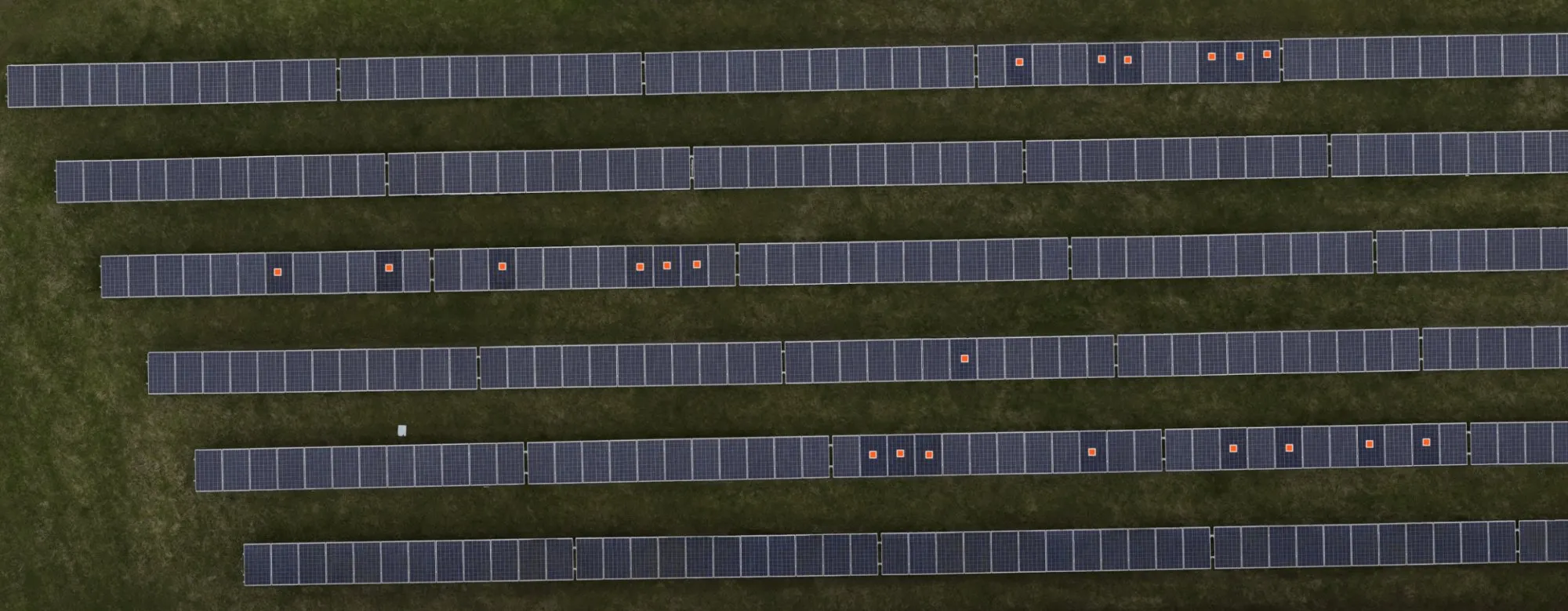

Identifying Mismatched Modules Across a Large Array

A solar farm in South Wales required a detailed inspection to identify mismatched PV modules — panels that differ visibly from their neighbours, often indicating incorrect replacements, mixed product batches, or warranty-relevant installation errors.

A traditional ground-based approach would have required walking every row of the array, multiple days on site with subjective visual judgement, manual GPS logging, and a high risk of missed defects across thousands of near-identical panels.

The client needed fast, accurate, and auditable results to support remedial works and asset management decisions.

Drone Imagery Meets AI-Powered Detection

We deployed high-resolution drone imagery across the entire site and processed the capture data through Scopito's AI-powered defect detection platform, enabling automated identification of mismatched modules.

Key elements of the delivery:

- Full aerial coverage captured by drone with georeferenced imagery

- AI-based detection automatically flagging mismatched modules across the array

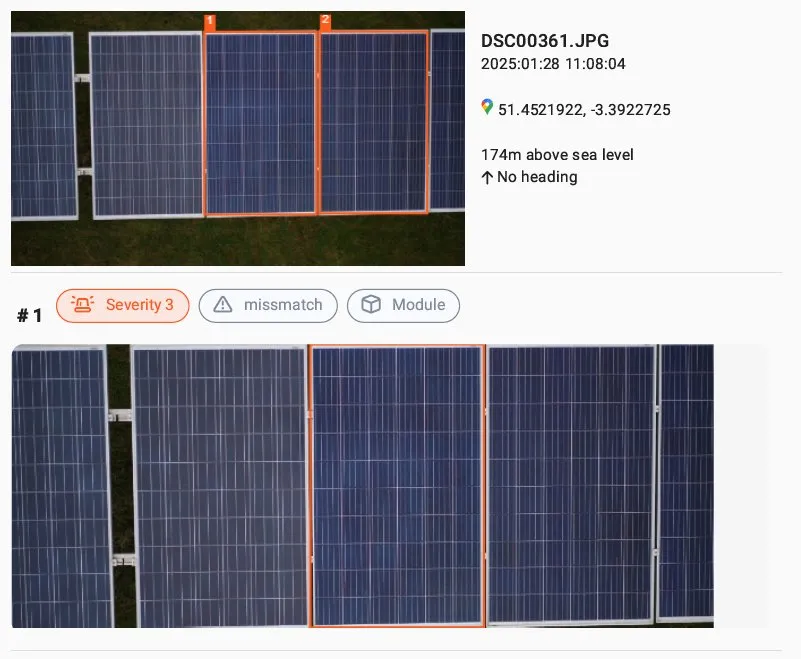

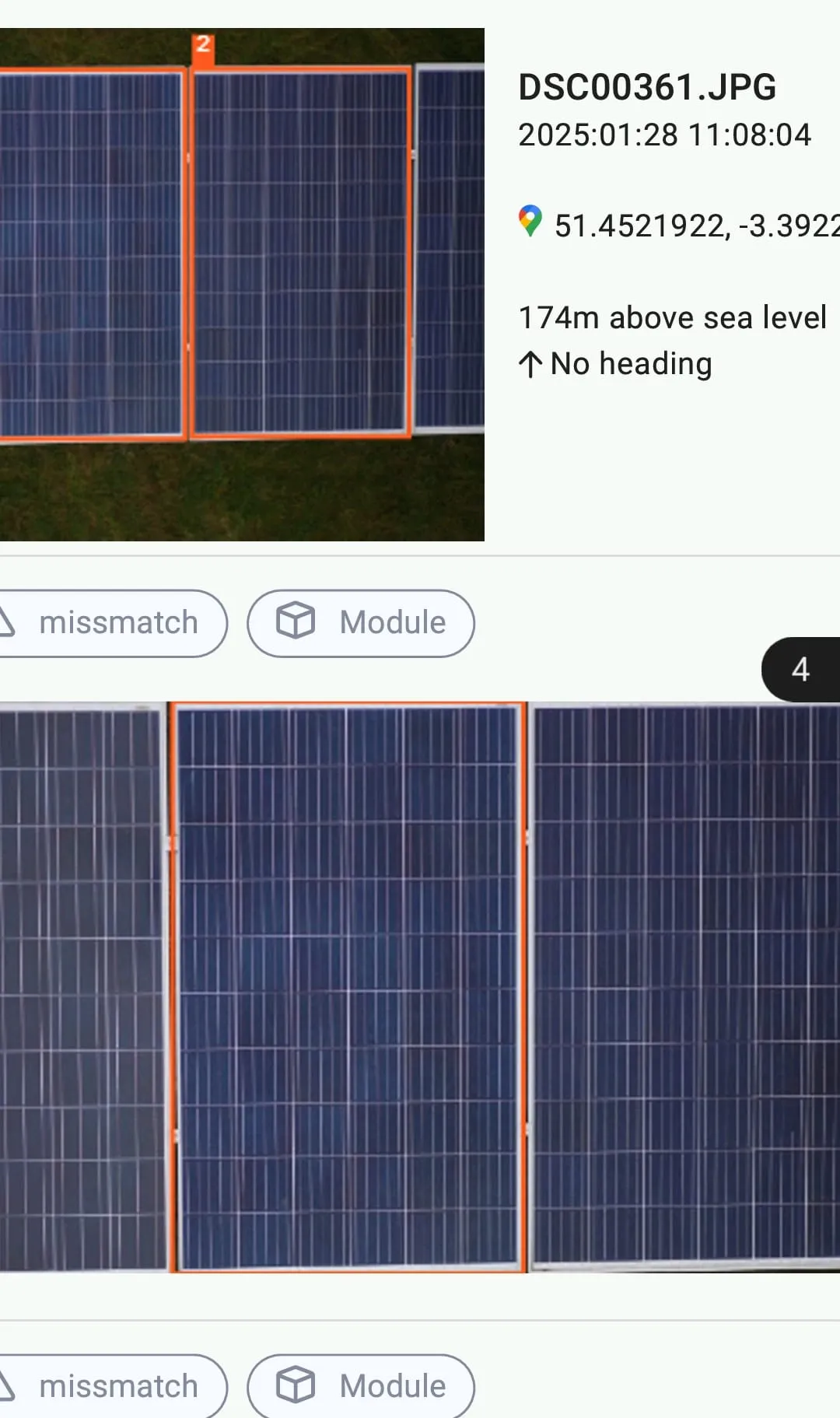

- Each detection tagged with severity rating, classification, and GPS coordinates

- No disruption to site operations during the inspection

- Elimination of subjective human judgement from the detection process

Precise, Actionable Findings

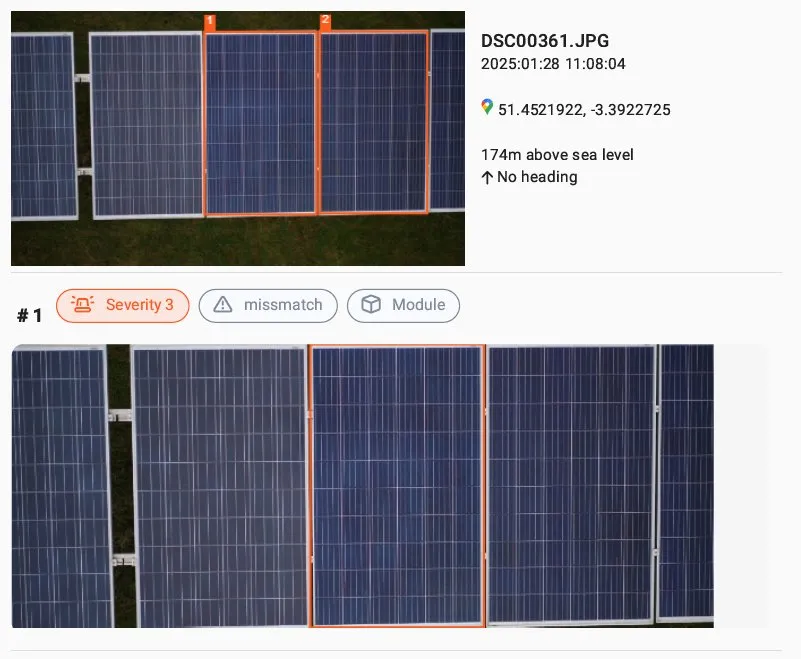

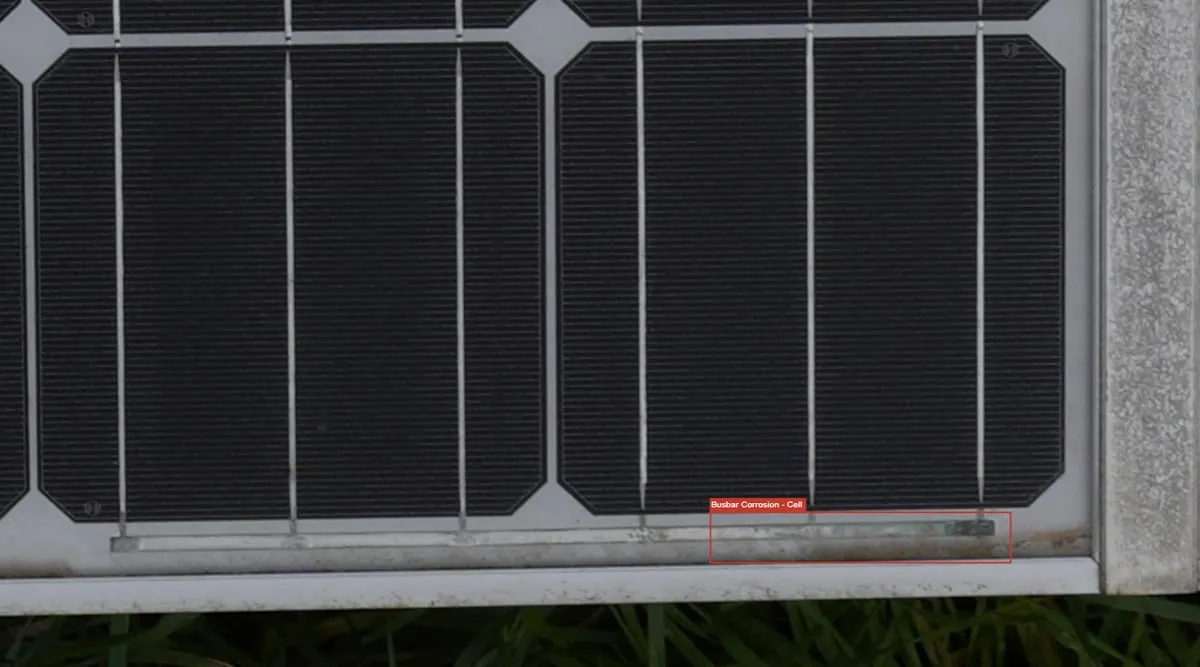

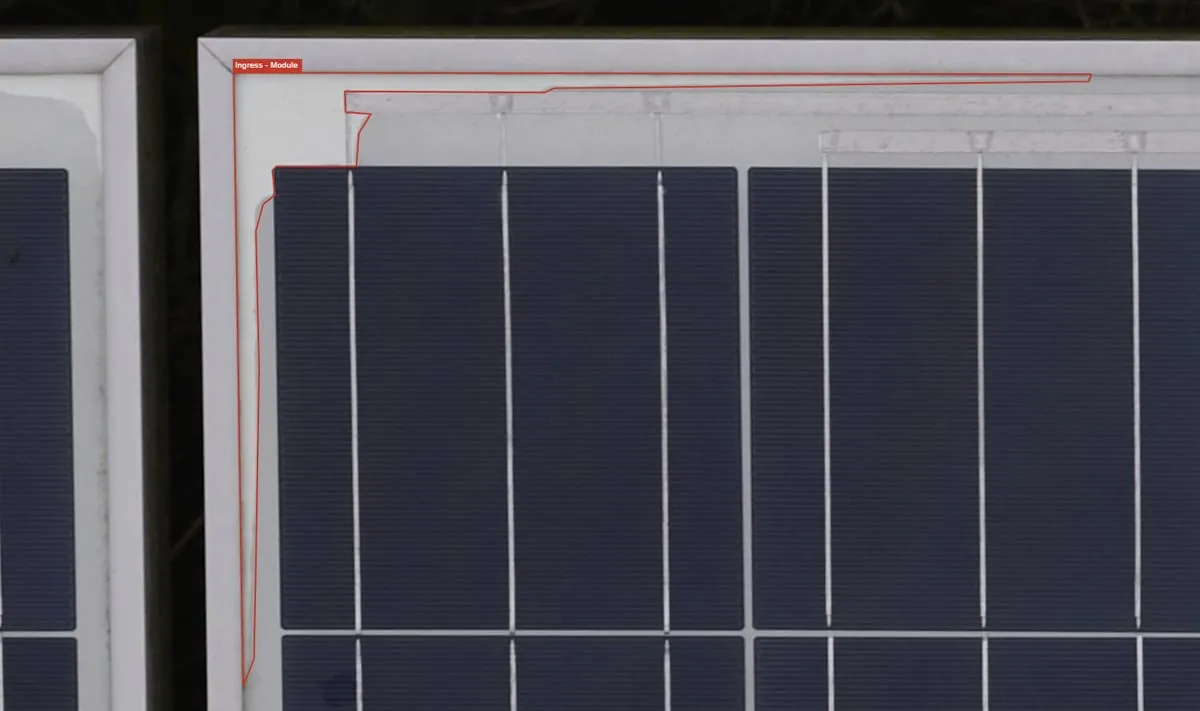

The AI processing identified 4 mismatched modules, all classified as Severity 3. The Scopito platform delivered structured severity overviews, annotated close-up imagery, precise GPS coordinates, and altitude and timestamp metadata for a complete audit trail.

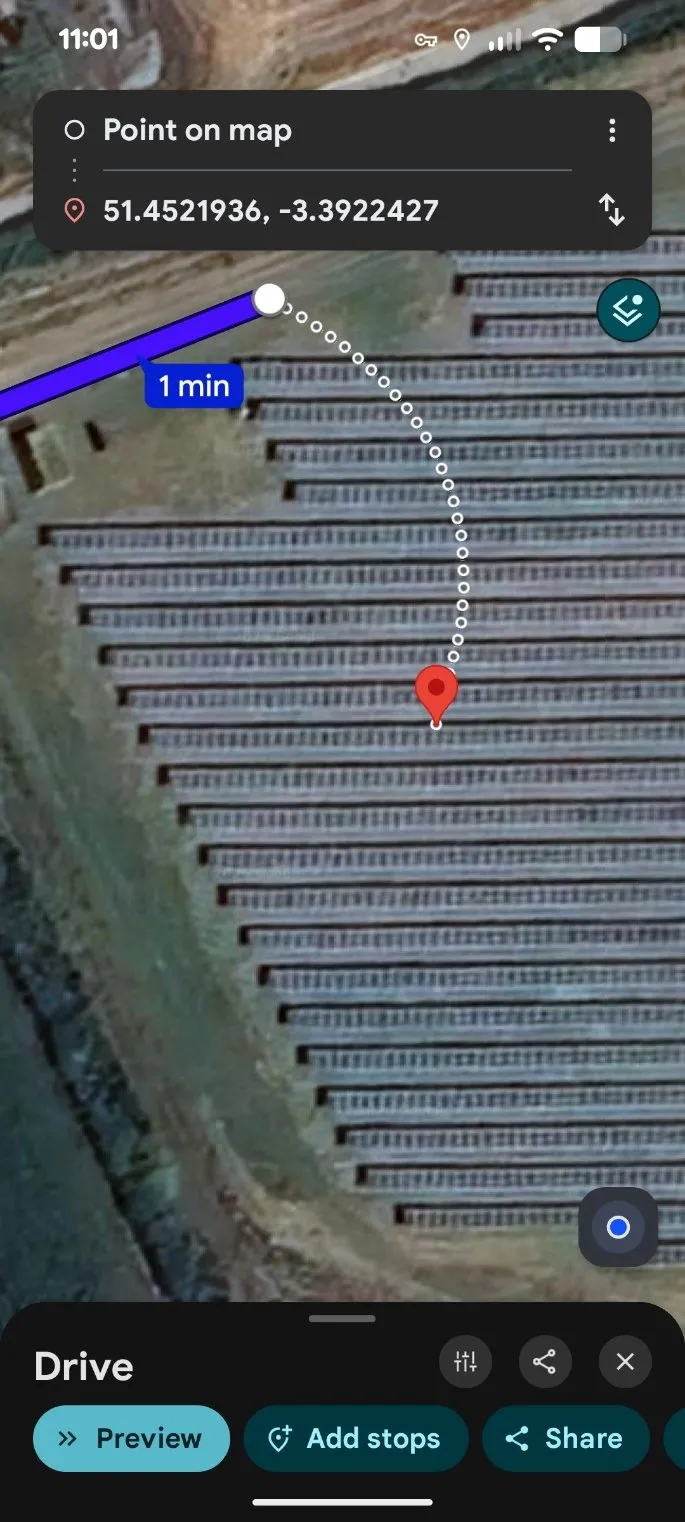

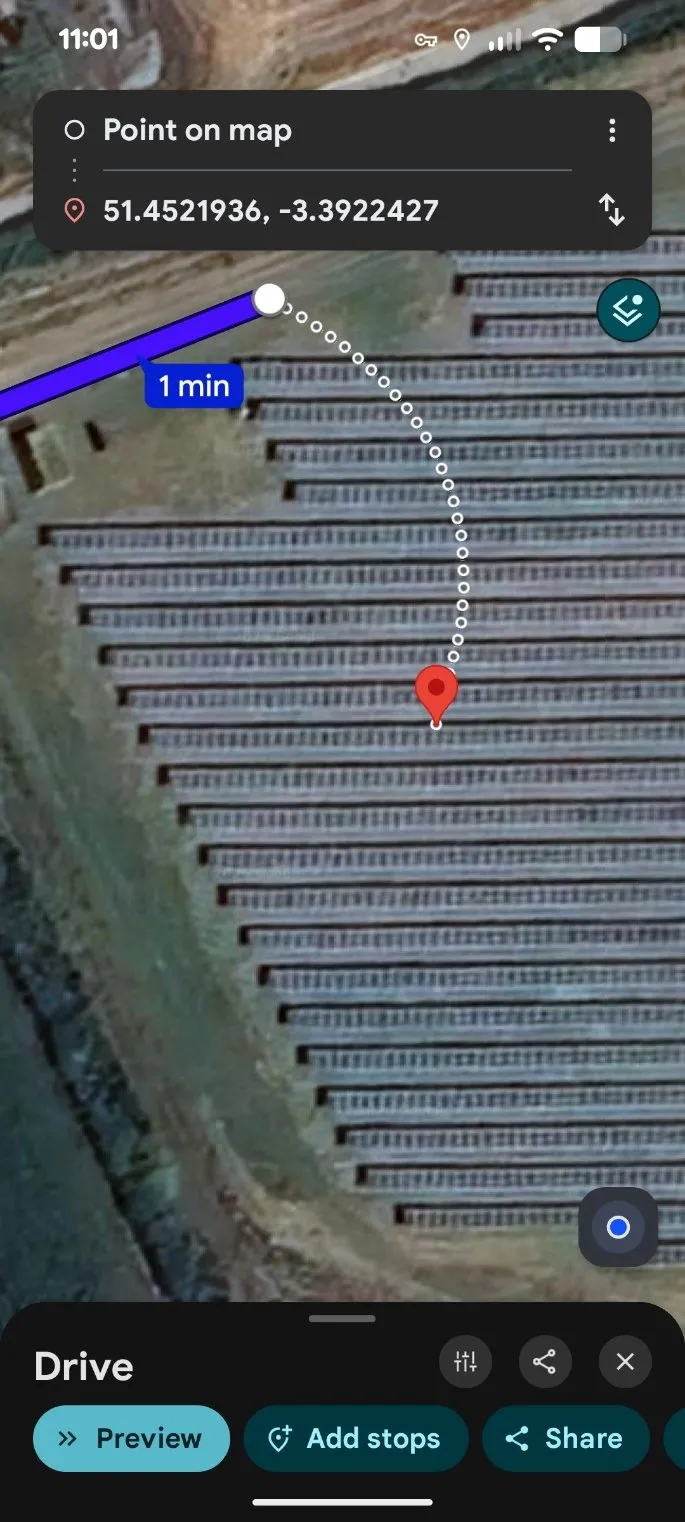

Engineers could navigate directly to the affected modules using their phones — no searching, no interpretation.

What the Client Gained

Speed

AI detection completed in a fraction of the time a manual inspection would require.

Accuracy

Every flagged module backed by high-resolution imagery and GPS evidence.

Engineer Efficiency

Direct mobile navigation to each affected panel — no searching on site.

Audit-Ready Reporting

Structured PDF output with severity ratings, metadata, and annotated imagery.

What the Client Received

AI Defect Report

Structured PDF with severity ratings, annotated close-up imagery, and classification tags.

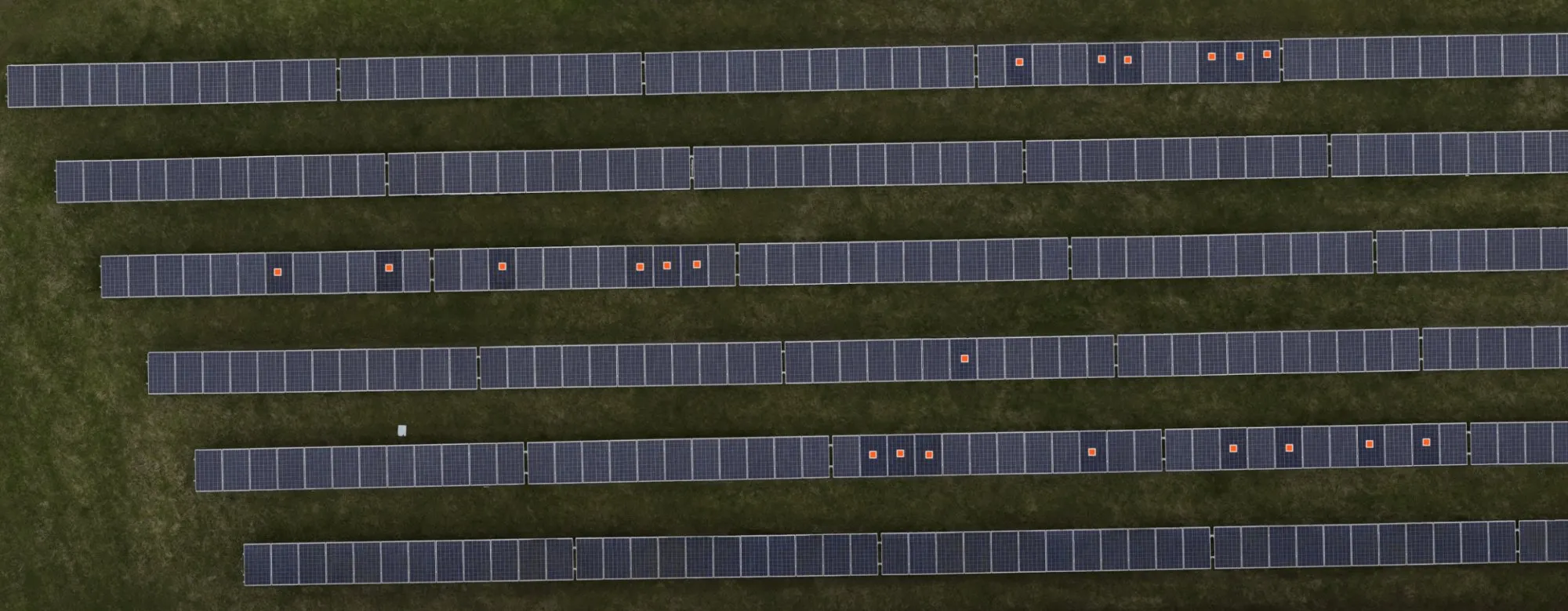

Site-Wide Panel Map

Full array map with markers showing detected mismatched modules and their locations.

Annotated Imagery

High-resolution aerial images with AI bounding boxes highlighting each detection.

GPS Navigation

Direct mobile links to each affected panel for fast on-site engineer access.

Why Mismatched Module Detection Matters

Mismatched modules are often nearly invisible from ground level, especially across large arrays. They're inconsistently recorded during manual inspections and can be indicative of wider quality control or warranty issues that require documentation.

By combining drone-captured imagery with AI-powered defect detection, we transform a slow, subjective task into a fast, objective, engineer-ready dataset. This project demonstrates how automated analysis can replace days of manual inspection with structured, audit-ready reports that support warranty claims and compliance requirements.

Explore Our Work

Market-Leading Serial Number Capture

Fast, precise, and verifiable panel-level data for asset managers, owners, and operators.

View Case Study →

Water Ingress & Serial Number Capture

A UK solar farm needing fast, accurate proof to activate a multi-million-pound warranty claim.

View Case Study →

Man vs Drone: The Statistics

Side-by-side comparison demonstrating drone inspection's 5x faster completion and zero safety incidents.

View Case Study →Need AI-Powered Inspection?

Get in touch with our team to discuss how drone-based AI analysis can support your solar asset management.