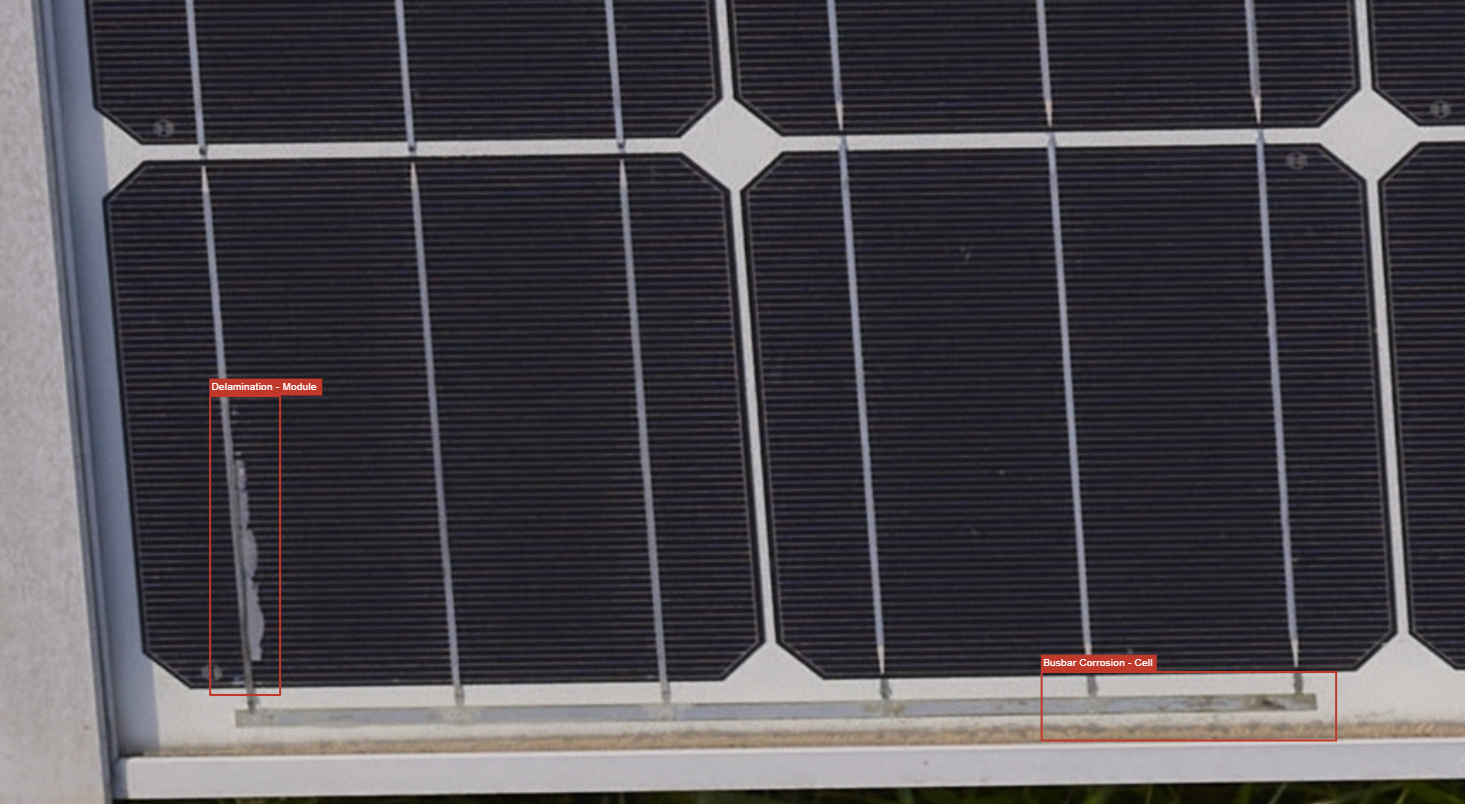

busbar corrosion delamination inspection

CASE STUDY: Detecting Busbar Corrosion & Delamination

Key Statistics:

Client:

Solar Asset Manager

Location:

South East, UK

Challenge:

Suspected widespread module degradation and corrosion.

Solution:

Ultra High-Resolution Visual Inspection

Result:

Identified 3200+ critical defects, enabling targeted replacement and preventing future losses

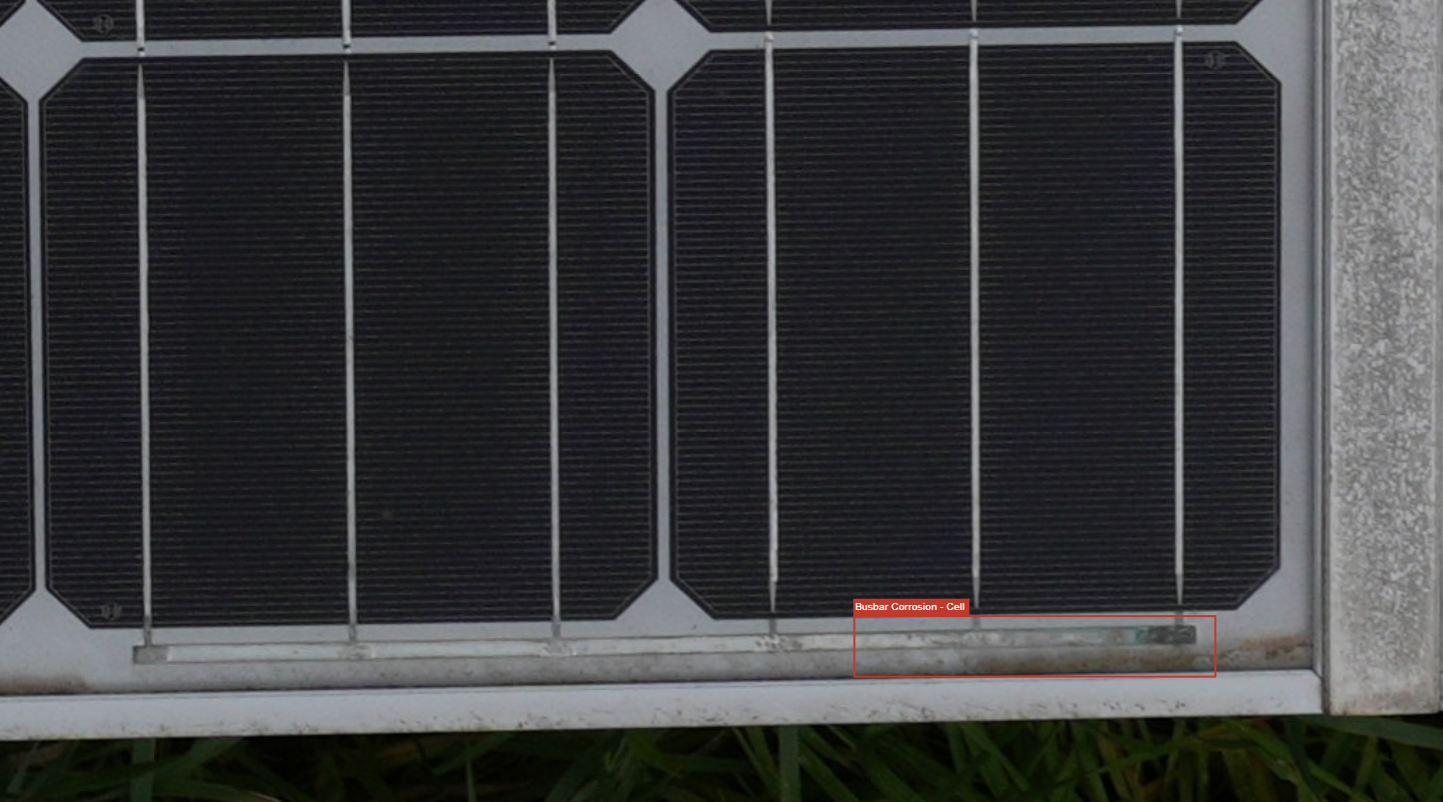

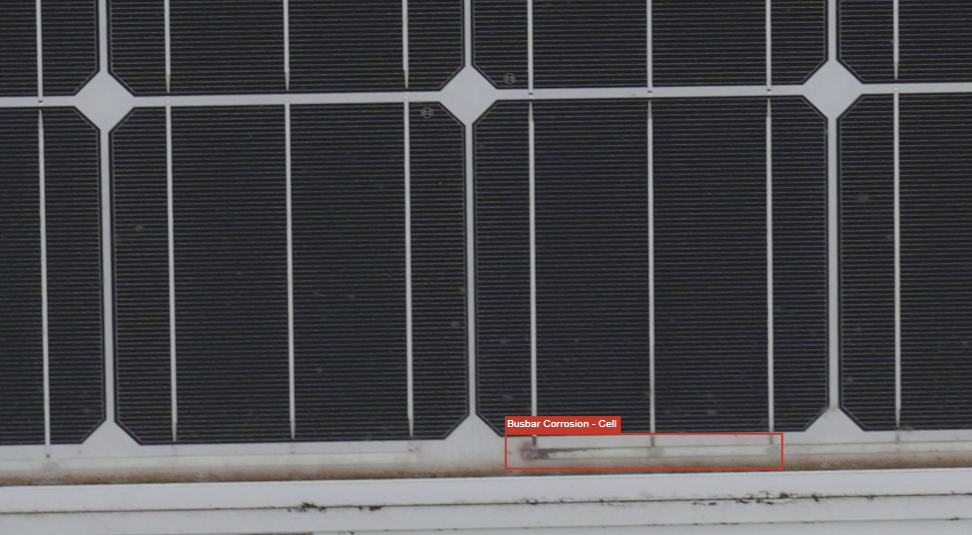

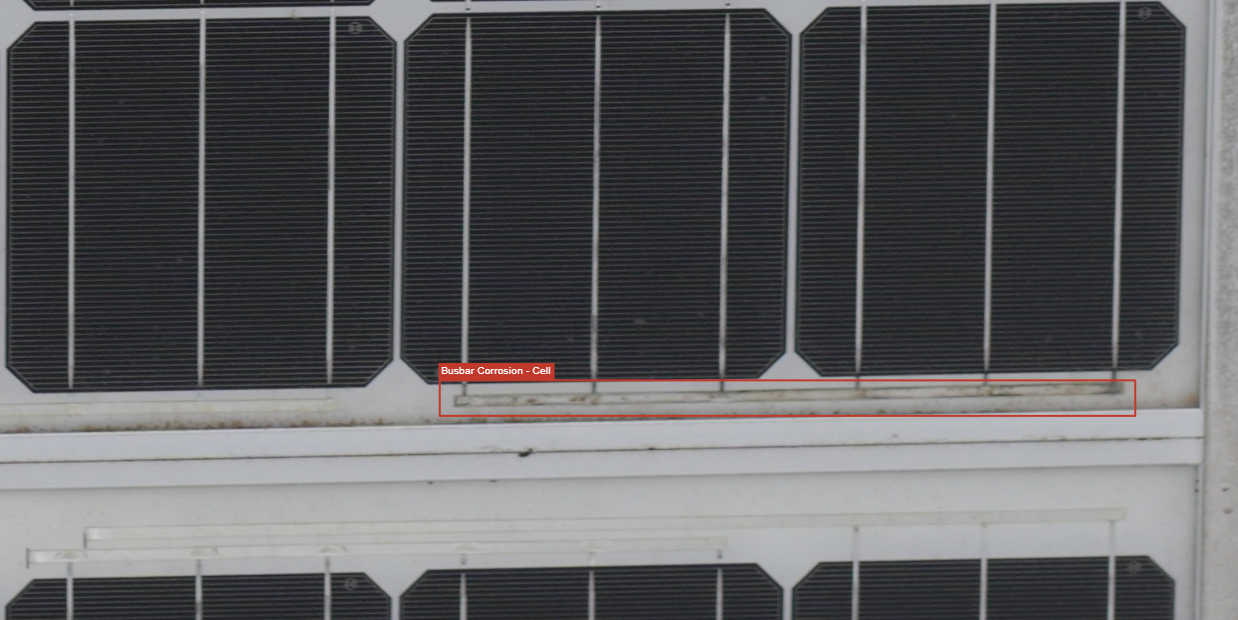

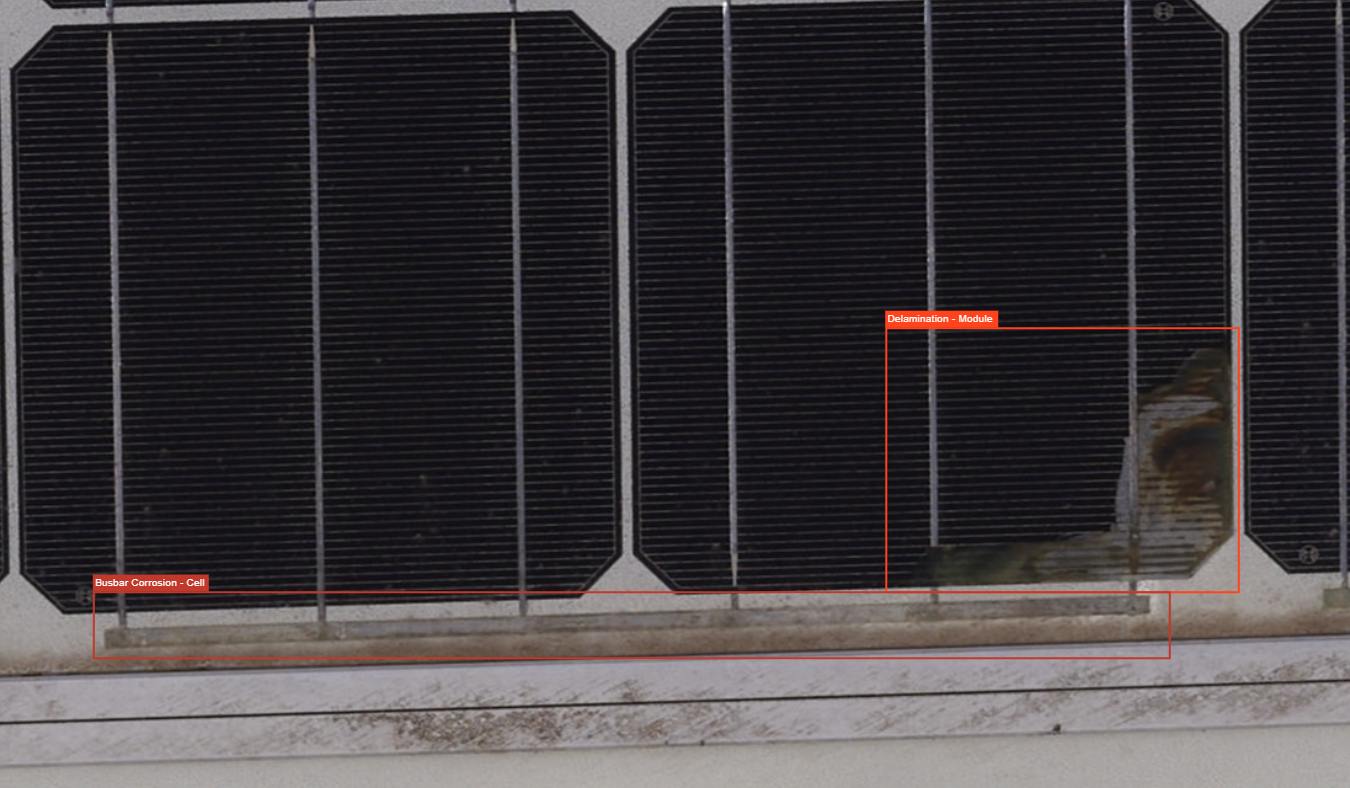

his case study details a recent busbar corrosion and delamination inspection for a large-scale solar farm in the UK. The asset manager was concerned these hidden defects could impact performance. According to industry bodies like Solar Energy UK, both issues are increasingly common and require this type of specialist detection. Our high-resolution aerial survey was deployed to provide the precise, panel-level data needed to assess the true condition of their assets.

The Challenge

An asset manager for a large-scale, ground-mounted solar farm in the UK suspected widespread module degradation across their portfolio. They were particularly concerned about difficult-to-detect issues like busbar corrosion and delamination, which are missed by standard aerial surveys. The client required highly detailed, panel-level data to accurately assess the condition of their assets and make informed decisions about future maintenance and replacements.

The Solution: Specialist Busbar Corrosion Inspection

Futurewise Aerial was commissioned to perform an ultra high-resolution visual inspection of the entire solar farm. Using our state-of-the-art aerial cameras, we captured imagery detailed enough to identify subtle, panel-level anomalies from the air

In addition to identifying the visual anomalies, our ultra high-resolution cameras allowed us to perform a second critical function on the same flight. We integrated our market-leading Solar Panel Serial Number Capture service to create a complete, verifiable asset registry.

This powerful combination cross-referenced the visual damage (like corrosion) with the exact panel serial number, providing the client with indisputable data for their warranty claims.

The Results

The inspection successfully identified over 250 panels with critical defects, including significant busbar corrosion that posed a long-term risk to the farm’s performance. By providing granular, panel-level data, we enabled the asset manager to move beyond estimations and precisely quantify the extent of the degradation

Inspection Results: Images and Video

Inspection Results

Ready to Find Out More?

Get in Touch