This small 5MW solar PV farm is set in an idyllic part of the UK and it was a pleasure to go and inspect it.

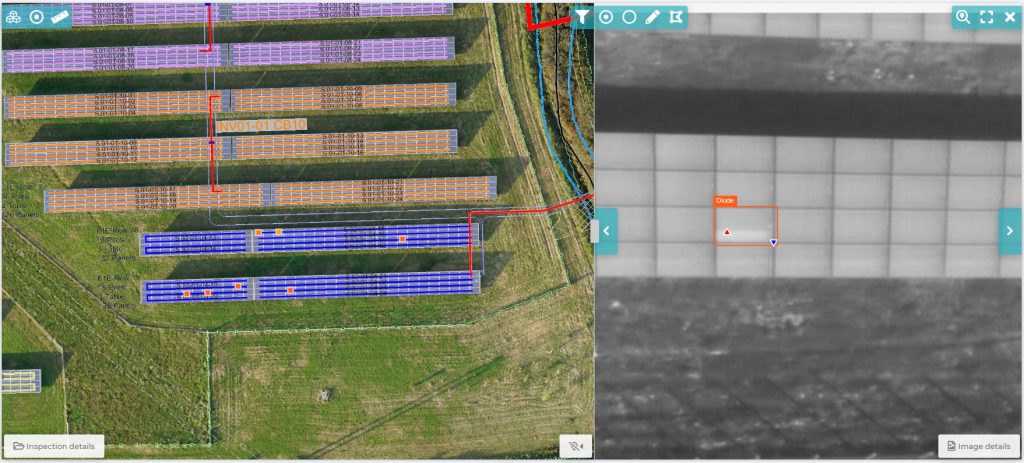

Unfortunately, not everything was quite so perfect under the surface and our inspection uncovered various anomalies, the most prevalent of which was issues with the ‘diode’.

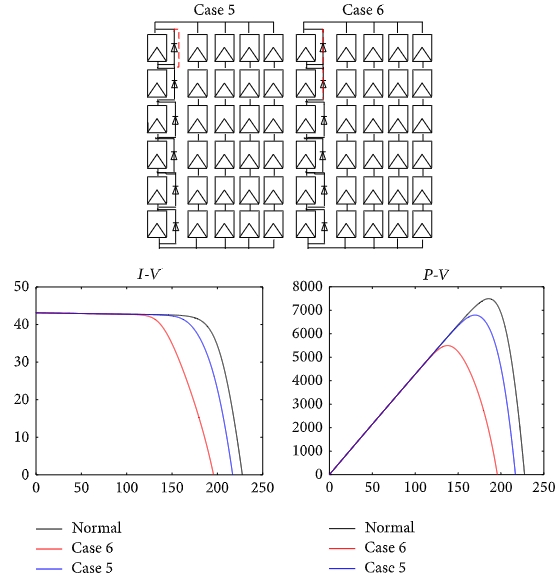

Bypass diodes are installed in PV modules to ‘shunt’ current around part of the module to protect it from being damaged if a fault or shading develops. Typically there are 3 bypass diodes protecting 20 or 24 PV Cells which is why the thermal pattern is usually very definitive (1/3rd of the module will be at a higher temperature).

This can be because the diode is activated or blown. Sometimes the junction box can be accessed and inspected for loose connections and other times the junction box can be sealed and it therefore becomes a warranty issue.

Although 1/3 of a module does not seem like too much of a concern, such a fault has a knock-on effect by restricting the current flowing in the rest of the series circuit (the string), thereby affecting the generation of approx 18-24 modules!

In this case above, we found 19 affected modules. Assuming strings of 20 x 300w modules we could estimate that 114KW or 2.28% of the system was being detrimentally affected.

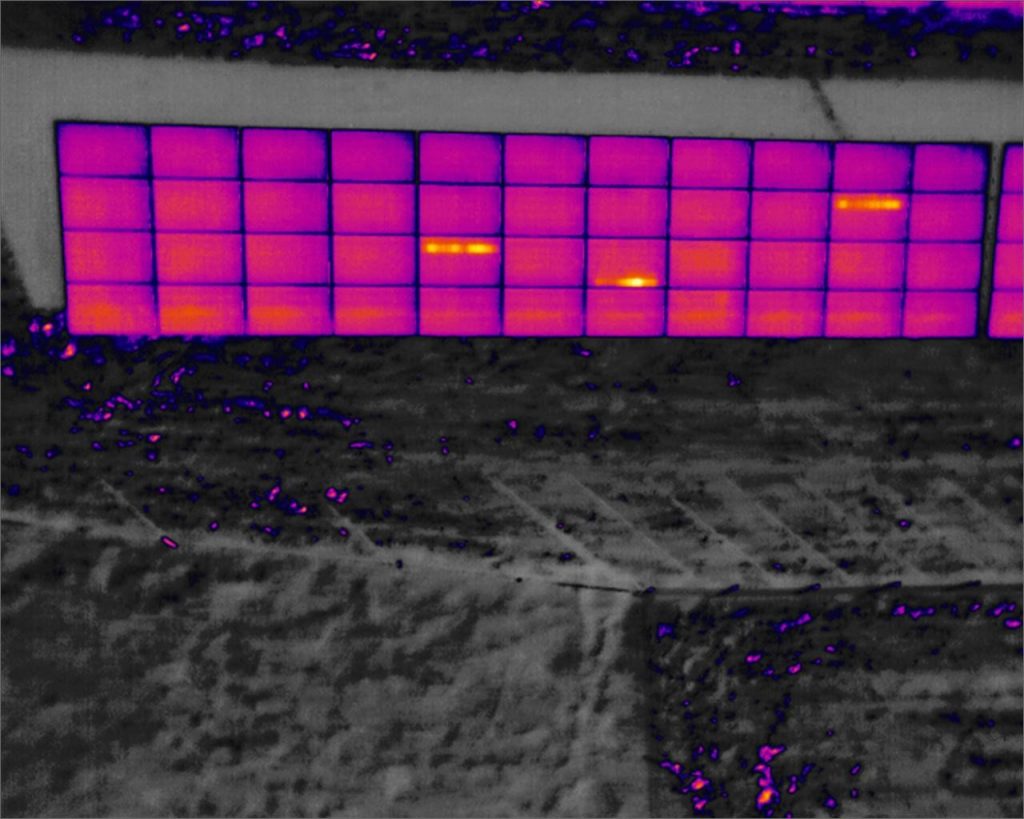

Although open-circuit substrings can sometimes be detected using a lower resolution quality thermal inspection, it is preferable to collect data at 3cm resolution or less.

The above example shows some sub-string anomalies in which you can see the thermal signature is hotter on certain cells and is not uniform across the whole sub-string.

This is a sign that the sub string is likely in short-circuit and is valuable information for the on-site engineer.

CONTACT US NOW for more information.